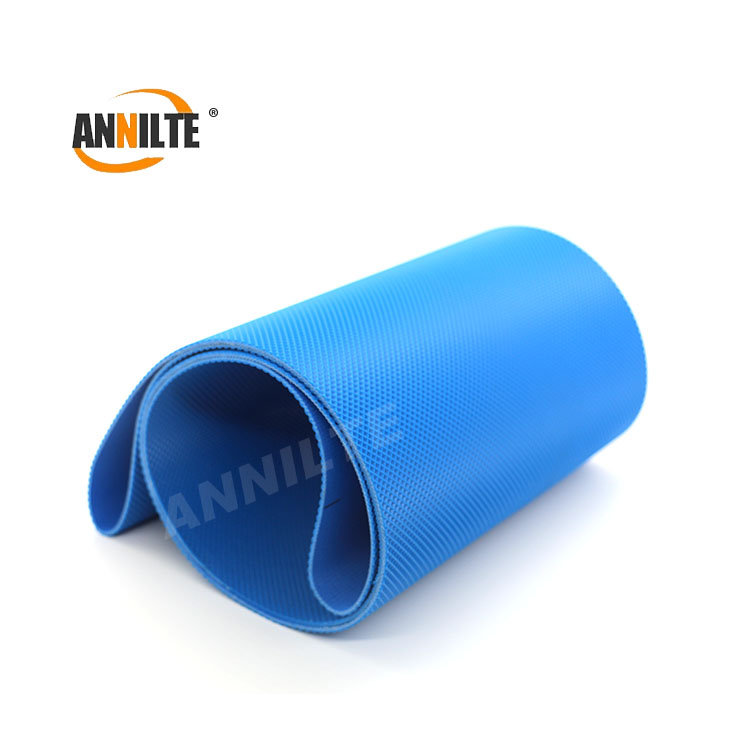

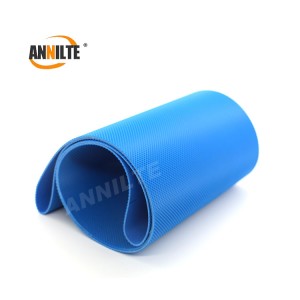

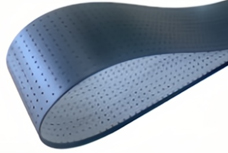

Premium PVC Diamond Pattern Conveyor Belt – The Ultimate Solution for Smooth & Efficient Material Handling

Why Choose Our PVC Conveyor Belt?

1. Superior Anti-Slip Performance

Diamond-shaped raised pattern enhances friction, preventing material slippage—perfect for inclined or high-speed conveying.

Excellent load stability, ensuring smooth transport of boxes, packages, food items, and more.

2. Durable & Long-Lasting

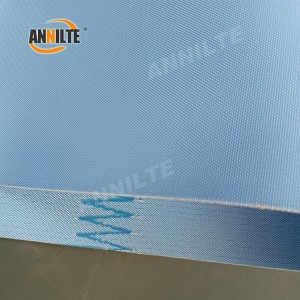

High-quality PVC material resists wear, tears, and abrasion, reducing downtime and replacement costs.

Reinforced fabric backing for added strength and flexibility, suitable for heavy-duty applications.

3. Lightweight & Easy to Maintain

Lighter than rubber belts, reducing motor strain and energy consumption.

Easy to clean & sanitize—ideal for food, pharmaceutical, and packaging industries (complies with FDA, EU, and other international standards).

Product Selling Points

Customized Scope

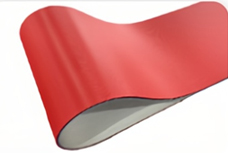

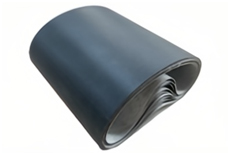

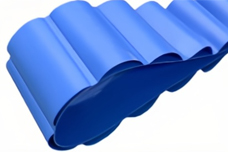

Annilte offers a wide range of customization options, including band width, band thickness, surface pattern, color, different processes (add skirt, add baffle, add guide strip, add red rubber), etc., which can meet the needs of different customers.

For example, the food industry may need oil and stain resistant properties, while the electronics industry needs anti-static properties. No matter which industry you are in, ENERGY can customize for you to meet the needs of various special working conditions.

Add skirt baffles

Guide bar processing

White Conveyor Belt

Edge Banding

Blue Conveyor Belt

Sponging

Seamless Ring

Wave processing

Turning machine belt

Profiled baffles

Applicable Scenarios

✔ Food Industry – Bakery, meat, seafood, frozen goods, and confectionery.

✔ Logistics & Warehousing – Parcel sorting, e-commerce fulfillment centers.

✔ Manufacturing – Electronics, automotive parts, and small component handling.

✔ Agriculture – Seed, grain, and vegetable transportation.

Industrial production

Biomass Pellet Conveying

Logistics

Fertilizer Bulk Conveying

Electronics Industry

Feed Conveying

Food Industry

Wine Lees Conveying

Quality Assurance Stability of Supply

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/