-

PP manure conveyor belt is a special equipment used for cleaning manure in farms. Its main advantages are reflected in the following aspects: 1. Excellent material: PP manure conveyor belt is made of pure virgin material, which has excellent impact resistance, low temperature resistance, corrosi...Read more »

-

Rubber canvas lifting belts have a variety of features that make them widely used in several industrial fields. Below are its main features: Excellent material: rubber canvas lifting belts are made of high-quality rubber and canvas material, which ensures good abrasion resistance, stretch resist...Read more »

-

Nylon transmission belt is also called high speed flat belt, which is made of high wear-resistant special synthetic rubber or leather as the friction layer, high strength nylon sheet base as the skeleton layer, the belt body structure is reasonable, with excellent comprehensive performance. Nylon...Read more »

-

Egg picker belts, also known as polypropylene conveyor belts or egg collection belts, are a special quality of conveyor belt. Its main advantages are reflected in the following aspects: Reduced egg breakage: The design of the egg collection belt helps to reduce the breakage rate of eggs during t...Read more »

-

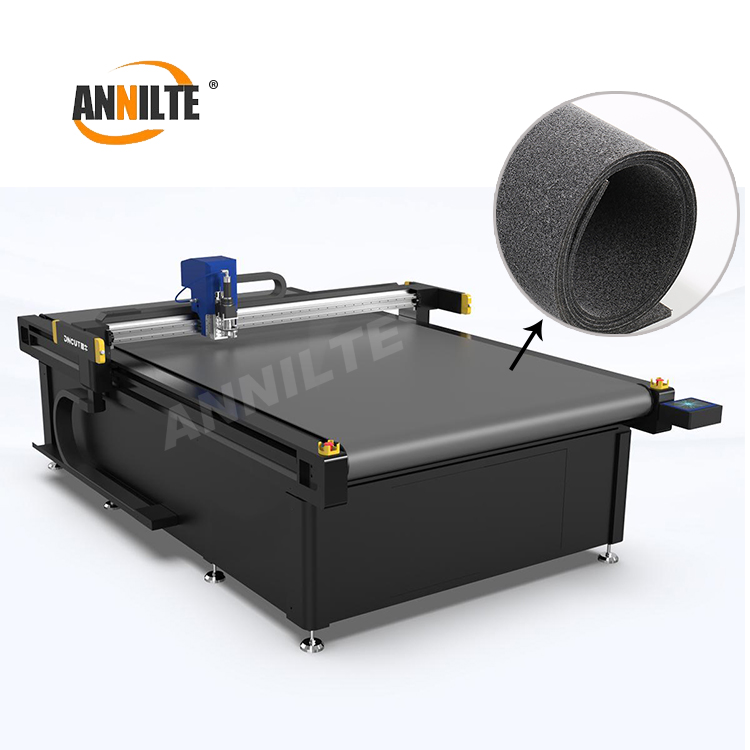

With the continuous development of the times, manual cutting has been eliminated by the market, vibratory knife cutting machine as an efficient, high-quality, low-cost cutting method, has been greatly sought after by the market.Annilte can provide vibratory knife cutting machine equipment manufac...Read more »

-

There is an old Chinese saying, “spring plowing, summer plowing, autumn harvest, winter storage”, now is the spring preparation for a good time, agricultural machinery products have ushered in the peak season of sales. Agricultural machinery plays an important role in modern agricultu...Read more »

-

Nowadays, more and more farms are choosing PP dung clean belt as the main way to clear manure, this article will introduce the reasons behind and the advantages of PP dung clean belt in detail. First of all, let’s understand the reasons for choosing PP dung clean belt. 1、 Improve the effic...Read more »

-

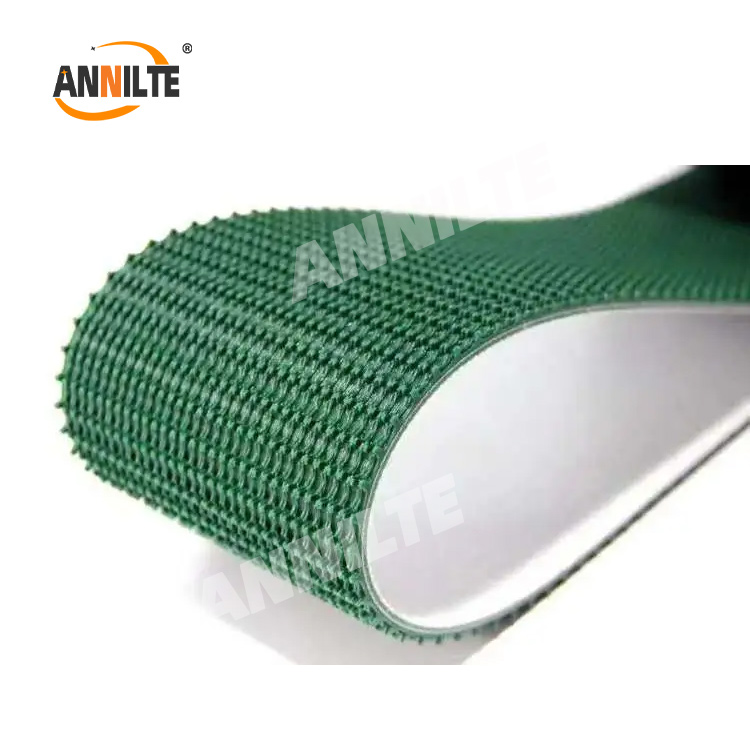

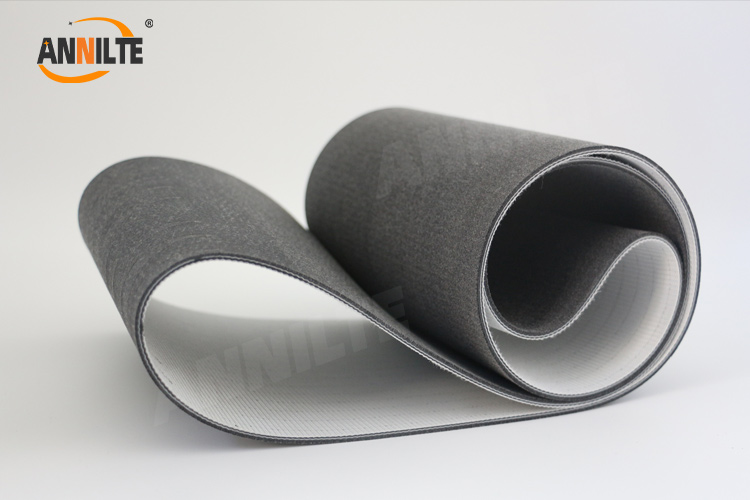

With the development of industrial automation, felt conveyor belts are more and more widely used in industry, which can be seen in cutting industry, logistics industry, ceramics industry, electronic processing industry and so on. Felt conveyor belt has two categories: single-sided felt conveyor b...Read more »

-

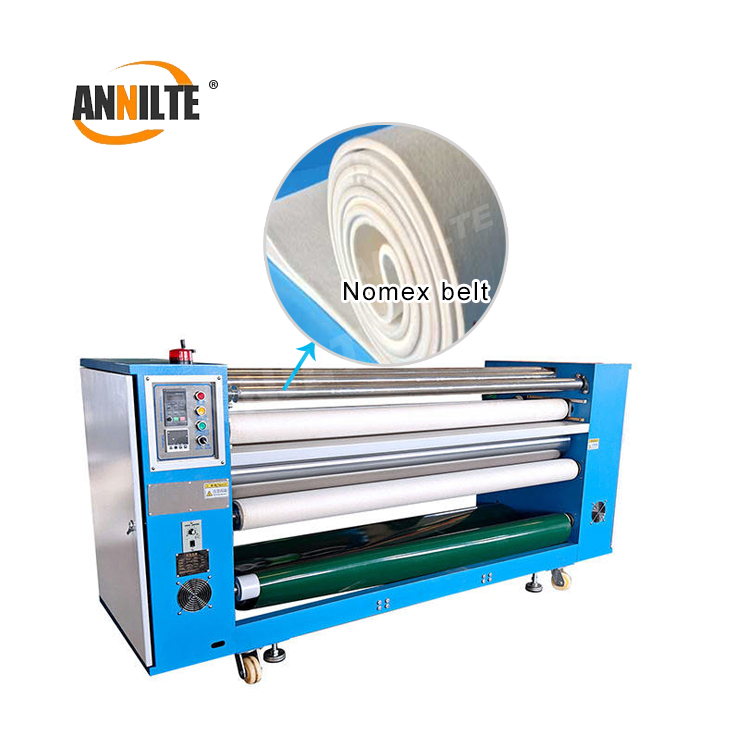

The characteristics of Nomex felt belts are mainly reflected in the following aspects: Excellent heat resistance: Nomex material itself has high heat resistance, which makes Nomex felt tape can maintain stable performance in high temperature environment, not easy to deformation or melting. Good e...Read more »

-

Nomex felted belts are used in a wide range of applications due to their unique performance characteristics. The following are the main application scenarios of Nomex felted belts: Protective clothing: Nomex felt belts are often used in the production of protective clothing due to their intrinsi...Read more »

-

Felt belts for digital cutting machines are specially designed belts for precise and efficient cutting operations with digital cutting machines. These belts are typically made of high-quality felt material that is shock-absorbent, stable and durable, ensuring accuracy and stability during the cut...Read more »

-

A chicken manure conveyor belt is a type of belt used in mechanical equipment that is used to transport chicken manure from one place to another. The design and manufacture of this type of conveyor belt requires consideration of a number of factors, including its size, material, support structure...Read more »

- Phone: +86 18560196101

- E-mail: 391886440@qq.com