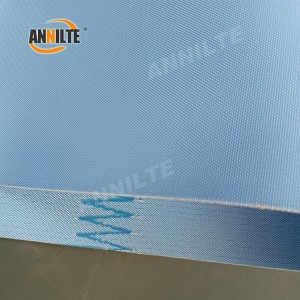

Annilte Factory Direct PVC Conveyor Belt PVC Transport Belt Manufacturers

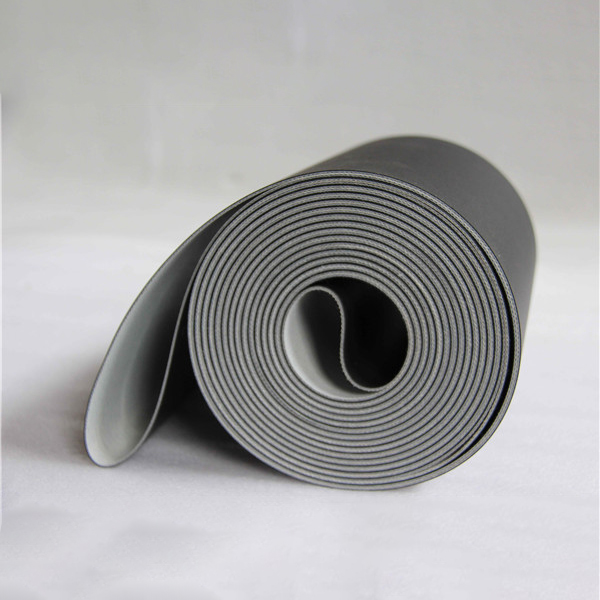

PVC conveyor belts can be divided into different colors (red, yellow, green, blue, grey, white, black, dark blue-green, transparent) and thicknesses according to the thickness and color of the products.

Thickness from 0.8MM to 11.5MM can be produced. Width from 10-10000mm can be processed.

Specification

| Thickness | 0.5-12mm |

| Width | ≤3000mm |

| Material | PVC /PU |

| Color | Green, white, petrol green, black, grey, dark grey, dark green, sky blue, orange, yellow, transparent, etc. |

| Pattern | Smooth, diamond, saw tooth, both way saw tooth, rough top, matt, squire rough top, stripe, dot, lozenge, checker, golf, wave rough |

| top, herringbone, treadmill, mini-grip, crescent, tape, majiang, solid-woven, sort tooth, etc. | |

| No. of Plies | 1ply, 2plies, 3plies, 4plies, and so on |

| Coating's Feature | Antistatic, thicker, harder, deeper, softer, fire-resistant, oil-resitant, cold-resistant, etc. |

| Fabric's Feature | Flexible, kevlai, felt, low-noise, jogger, cotton |

detail

| Description | Minimum Pulley Ø | N/mm @ 1% Elongation | Temp ⁰C | Thick | Kg/m² | ||

|

2Ply Bare PVC Top X Bare Bottom | 25 | 10 | -10⁰ to +80⁰ | 1,8 | 1,7 | |

| 3Ply Bare PVC Top X Bare Bottom | 60 | 18 | -10⁰ to +80⁰ | 2,9 | 3,0 | ||

| 2Ply Friction PVC Top X Bare Bottom | 25 | 10 | -10⁰ to +80⁰ | 1,8 | 1,7 | ||

| 3Ply Friction PVC Top X Bare Bottom | 60 | 18 | -10⁰ to +80⁰ | 2,9 | 3,0 | ||

|

3Ply White PVC Top X Bare Bottom | 100 | 15 | -10⁰ to +80⁰ | 3,8 | 4,0 | |

| 3Ply 3mm White PVC Top X Bare Bottom | 100 | 15 | -10⁰ to +80⁰ | 5,9 | 5,1 | ||

| 3Ply 2mm White PVC Top X 1mm PVC Bottom | 120 | 18 | -10⁰ to +80⁰ | 6,2 | 7,8 | ||

| 1Ply White PU X Bare Bottom | 4 | 3 | -10⁰ to +80⁰ | 0,7 | 0,7 | ||

| 2Ply White PU X Bare Bottom | 6 | 5 | -10⁰ to +80⁰ | 1,1 | 0,8 | ||

|

2Ply Green PVC Too X Bare Bottom | 30 | 8 | -10⁰ to +90⁰ | 2,0 | 4,1 | |

| 3Ply Green PVC Top X Bare Bottom | 120 | 15 | -10⁰ to +80⁰ | 3,8 | 2,3 | ||

|

2Ply Blue PU Top X Bare Bottom | 6 | 6 | -10⁰ to +80⁰ | 1,3 | 0,7 | |

|

2Ply Blue PVC Top X Bare Bottom | 30 | 8 | -10⁰ to +80⁰ | 2,0 | 2,3 | |

| 2Ply Blue PVC Top X Bare Bottom | 100 | 13 | -10⁰ to +80⁰ | 4,6 | 5,0 | ||

|

2Ply Black Checkout PVC Top X Bare Bottom | 30 | 8 | -15⁰ to +80⁰ | 2,0 | 2,3 | |

|

2Ply White PVC Diamond Top X Bare Bottom | 30 | 8 | -10⁰ to +90⁰ | 2,1 | 2,1 | |

|

2Ply Blue PU Diamond Top X Bare Bottom | 10 | 6 | -20⁰ to +80⁰ | 1,7 | 1,6 | |

|

2Ply White PVC Rib Top X Bare Bottom | 60 | 10 | -10⁰ to +70⁰ | 6,0 | 5,3 | |

|

2Ply White PVC Sawtooth Top X Bare Bottom | 60 | 10 | -10⁰ to +90⁰ | 5,0 | 5,3 | |

|

2Ply Black PVC Longitudinal Top X Bare Bottom | 60 | 10 | -10⁰ to +90⁰ | 3,1 | 3,2 | |

|

2Ply White PVC Horseshoe Top X Bare Bottom | 60 | 10 | -10⁰ to +90⁰ | 5,0 | 6,1 | |

|

2Ply Black PVG Padlefoot Top X Bare Bottom | 51 | 21 | -29⁰ to +82⁰ | 6,4 | 4,5 | |

|

2Ply Black PVC Basket Weave X Bare Bottom | 40 | 8 | -15⁰ to +80⁰ | 2,4 | 2,5 | |

|

2Ply Blue PVC Roughtop X Bare Bottom | 60 | 10 | -20⁰ to +70⁰ | 5,5 | 4,4 | |

|

2Ply Blue PVC Crockback Top X Bare Bottom | 80 | 10 | -10⁰ to +80⁰ | 7,5 | 6,0 | |

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/