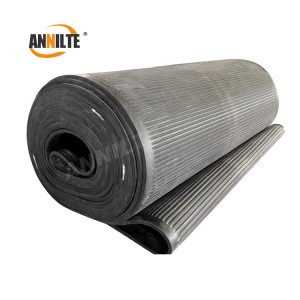

High temperature conveyor belt

High Temperature Conveyor Belt,Heat Resistant and Scorch Resistant Conveyor Belt,High Temperature Resistant and Scorch Resistant Conveyor Belt for Clinker in Cement Plant,High Temperature Resistant and Scorch Resistant Conveyor Belt for Slag in Steel Plant,Extend the life span of High Temperature Resistant Conveyor Belt by about one month to six months compared with the general High Temperature Resistant Conveyor Belt.

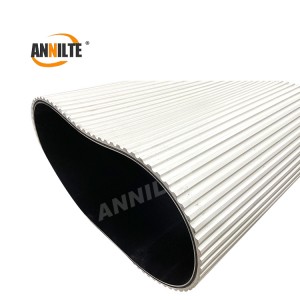

The temperature of conveyed materials can reach over 200℃, and can reach 800℃ instantaneously, which is suitable for all the occasions where ordinary heat-resistant conveyor belts are used.

Uses: Mainly used in metallurgy, coking, metallurgical industry and other industries.

Mainly used in metallurgy, coking, iron and steel, foundry industry, sintered ore, cement clinker and other materials at a particularly high temperature (not more than 500 ℃) conveyor.

Features.

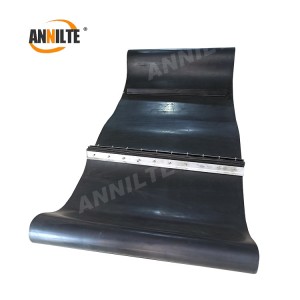

1、The strong layer adopts new type of high strength, low shrinkage polyester canvas or high temperature resistant steel mesh.

2、Covering layer adopts unique adhesive formula to form an adiabatic carbonised layer on the surface when conveying high temperature materials.

3. The adhesive formula ensures high adhesion between the cover layer and the fabric layer under high temperature conditions, avoiding blistering and delamination of the adhesive layer in the process of use, with good stability and long service life.

Suggestions for selection: The surface temperature of the belt is closely related to the service life of the heat-resistant tape, which directly affects the adhesive strength between the covering rubber and the core of the tape, and the abrasion resistance and anti-cracking of the covering rubber, etc. The surface temperature of the belt is closely related to the service life of the heat-resistant tape. The surface temperature of the belt body is closely related to the composition, nature and surface structure of the conveyed materials. The larger the contact area between the material and the surface of the belt, the worse the heat dissipation of the belt; the longer the conveying distance, the better the heat dissipation. Therefore, when selecting high temperature conveyor belt, we should fully investigate and measure the surface temperature of the belt, and fully consider the type of material and the length of the conveyor line and other factors. Thicker cover rubber is an important condition to ensure the long life of the belt, we suggest that under high temperature environment, the upper cover rubber 6mm~8mm, the lower cover rubber 2~4mm.