Annilte endless coil wrapper belts with TPU coating on both sides for steel plate and aluminum plate rolled

- In the metal industry, wrapping or winding machines are used to coil the metal roll material (steel, aluminum, copper) of variable thickness. The wrapping or coiling belts are positioned around the mandrel and force the sheet to start coiling as it is fed between the belt and the mandrel. The belts are impacted by the leading sharp edges of the metal rolls and are additionally exposed to chemicals from milling emulsions.

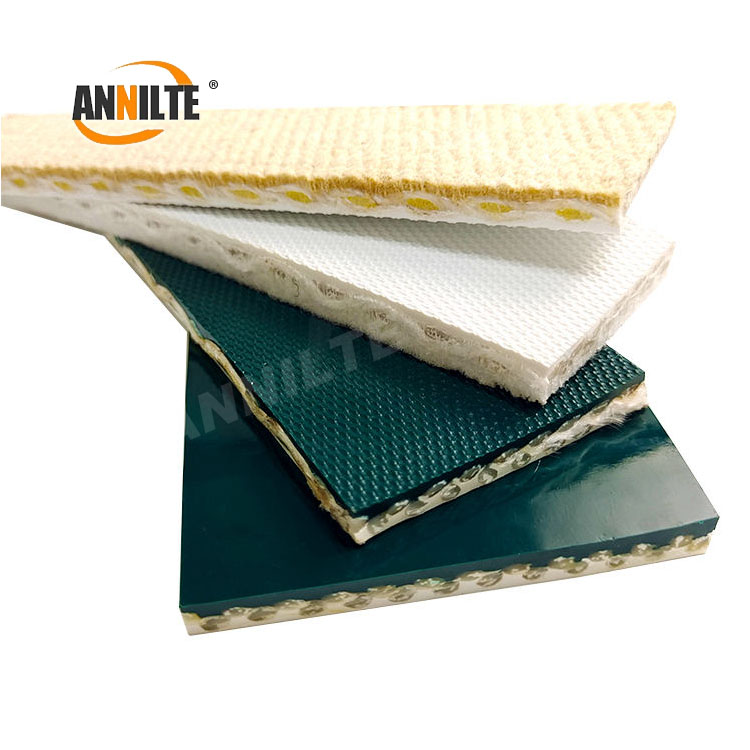

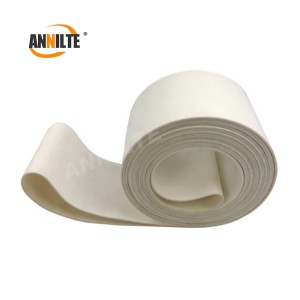

XZ’S belt is a low stretch belt designed with a PET endless woven, high strength carcass featuring TPU coating on the conveying and running sides. This provides excellent cut, abrasion, and impact resistance against the leading end of metal coils.

Features:

-

Highly durable / longer belt life

-

TPU cover won’t harden or crack due to emulsion chemicals

-

Low stretch characteristics leading to better tracking

-

Endless woven design

-

1-12mm cover thicknesses available ,Also available with NOMEX cover

-

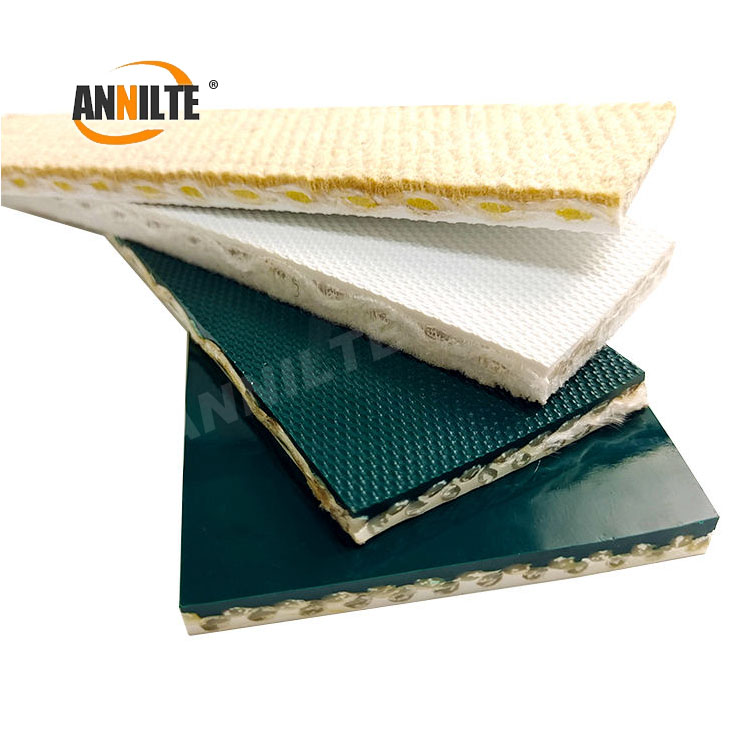

Coil wrapper belts product types

Currently there are four types of coil wrapper belts offered:

| Model | Main materials | Temperature resistance | Belt thickness |

| UUX80-GW/AL | TPU | -20-110C° | 5-10MM |

| KN80-Y | NOMEX | -40-500C° | 6-10MM |

| KN80-Y/S1 | NOMEX | -40-500C° | 8-10MM |

| BR-TES10 | RUBBER | -40-400C° | 10MM |