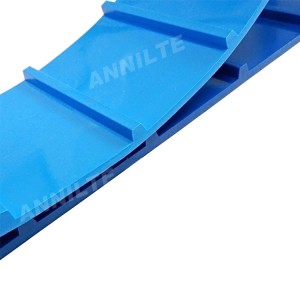

PE conveyor belt for tobacco, electronics, textile, printing

Why PE Conveyor Belts Are Essential for Tobacco Industry Success

Polyethylene (PE) conveyor belts have become the industry standard for tobacco processing for several critical reasons. These belts offer exceptional performance characteristics that align perfectly with the unique demands of tobacco manufacturing and handling.

Our Product Advantages

Hygiene & Safety Compliance

Our PE conveyor belts are manufactured with FDA-approved materials that meet strict food and pharmaceutical grade standards. This ensures zero contamination risk to your tobacco products, maintaining purity throughout processing, packaging, and distribution cycles.

Moisture & Chemical Resistance

Tobacco processing involves various humidity levels and occasional chemical exposures. Annilte PE belts provide excellent resistance to moisture, mildew, and most chemicals used in tobacco facilities, ensuring longevity and consistent performance.

Non-Stick Surface Properties

The smooth, non-porous surface of our PE conveyor belts prevents tobacco particles from adhering to the belt, reducing product loss and eliminating cross-batch contamination. This feature significantly simplifies cleaning procedures between production runs.

Durability & Low Maintenance

Engineered for continuous operation, Annilte PE belts demonstrate exceptional resistance to abrasion, tearing, and impact damage. Their robust construction translates to reduced downtime and lower maintenance costs over the belt's extended service life.

Why Choose Us

At Annilte, we don't just manufacture conveyor belts; we engineer solutions tailored to the tobacco industry's specific challenges. Our PE conveyor belts incorporate several proprietary features:

- Customizable Surface Textures: We offer various surface finishes optimized for different tobacco processing stages, from initial leaf handling to final packaging.

- Precision Tracking Systems: Our belts include integrated tracking features that minimize alignment issues and reduce edge wear.

- Temperature-Stable Formulations: Specialized PE compounds maintain flexibility and strength across a wide temperature range suitable for tobacco processing environments.

- Anti-Static Options: Available with anti-static properties to prevent dust accumulation and discharge risks in sensitive areas.

Applicable Scenarios

Annilte PE conveyor belts serve multiple critical functions throughout tobacco production:

- Primary Processing: Gentle handling of tobacco leaves during sorting, drying, and conditioning

- Cut Tobacco Conveyance: Efficient transport of cut tobacco with minimal degradation

- Packaging Lines: Reliable movement through weighing, portioning, and final packaging stations

- Warehouse Distribution: Durable handling in storage and dispatch operations

Quality Assurance Stability of Supply

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/