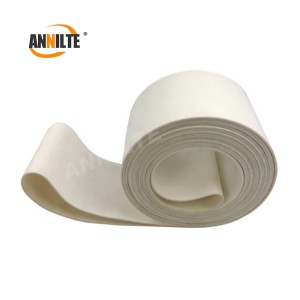

Endless woven and needle felt with silicone coating for Pressing machine

A silicone-coated Nomex felt belt is a specialized industrial conveyor belt designed for high-temperature and non-stick applications.

Specification

Infinite perimeter, width within 2 metres, thickness 3-15mm, structure of the bottom felt surface silicone, white/red appearance, thickness error ± 0.15mm, density 1.25, long-term temperature resistance of 260, instantaneous temperature resistance of 400, the use of laminating machines, ironing and dyeing, drying and extrusion industries

Our Product Advantages

Non-stick properties – Ideal for applications involving adhesives, resins, or sticky materials.

Heat resistance – Silicone can handle temperatures up to 230°C (446°F) continuously.

Flexibility & release properties – Prevents materials from adhering to the belt.

Chemical resistance – Resists oils, solvents, and some acids/alkalis.

Flawless Flatness – Our knife-coating & roller application ensures even distribution without bubbles or ridges.

Applicable Scenarios

Hot melt lamination – Used in textile, automotive, and composite manufacturing.

Printing & drying processes – For heat-setting inks or coatings.

Food processing – Non-toxic silicone variants may be used in baking or drying.

Plastic & rubber processing – Prevents sticking during curing or molding.

Electronics manufacturing – Used in PCB lamination or flexible circuit production.

Quality Assurance Stability of Supply

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/