Customized Silicone Conveyor Belt for Vermicelli Machine

In the competitive food processing industry, choosing a high performance, durable and safe conveyor belt is critical. Our food grade silicone conveyor belts are optimized for vermicelli, cold skin and rice noodle production equipment, and have the following irreplaceable advantages over ordinary products in the market:

Our Product Advantages

1. 100% food-grade safety, in line with international certification

FDA, LFGB, SGS certification, to ensure non-toxicity, no odor, long-term contact with food without risk.

No plasticizers, heavy metals, to avoid contamination of the powdered skin, in line with the export of Europe, America, Japan and South Korea and other high standard market requirements.

Comparison: some low price silicone bands on the market use industrial grade silicone, which may release harmful substances and affect food safety!

2. High temperature resistance 250 ℃, cooking without deformation

-60℃~250℃ Wide temperature range is applicable, whether it is high-temperature steaming or low-temperature cooling, stable performance.

Anti-aging: long-term high-temperature environment is not easy to harden, cracking, life expectancy is 3-5 times that of PU tape.

Case: A customer originally used PU belt, the cooking section is replaced every 3 months; after changing to our silicone belt, no damage for 2 years!

3. Super anti-adhesion, reduce downtime cleaning time

Smooth surface, vermicelli, rice noodle automatic demolding, no need to scrape away manually.

Non-stick starch, grease, cleaning only need a damp cloth to wipe, downtime maintenance time reduced by 50%.

Measurement comparison:

Ordinary PU belt: 2 hours sticking, need to stop and clean

Our silicone belt: 8 hours continuous work without adhesion

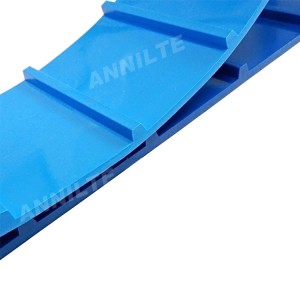

4. Customized service to perfectly match your equipment

Size customization: width (10cm~2m), thickness (1mm~10mm), color (transparent/white/black).

Functional upgrades: can be added with deflector groove, perforation, anti-running design, suitable for all kinds of vermicelli machine models.

72 hours sampling, 15 days fast delivery, priority arrangement for urgent orders!

Applicable Scenarios

In food processing lines such as vermicelli, cold skin, rice noodles, etc., the performance requirements of conveyor belts vary in different process sections. Our food-grade silicone conveyor belts can be perfectly adapted to core production by virtue of their high temperature resistance, anti-sticking, flexibility and other characteristics.

Quality Assurance Stability of Supply

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/