Proposal for Replacement Conveyor Belt: Metso CBD-60-B6GP-C000578-001

The High Cost of Wollastonite Abrasion on Standard Belts

Standard conveyor belts simply aren’t cut out for wollastonite. The sharp, hard particles act like sandpaper, causing:

- Rapid Top Cover Wear: Leading to material slippage and reduced efficiency.

- Carcass Damage: Exposing the belt’s internal fabric or steel cords, risking catastrophic failure.

- Increased Energy Consumption: Worn surfaces create more friction.

- Contamination: Belt debris can mix with your high-purity wollastonite product.

We have thoroughly reviewed your technical specifications for the replacement conveyor belt on your Metso equipment. Specifically for the model CBD-60-B6GP-C000578-001, we are pleased to present our dedicated high-performance belt solution. It is engineered for perfect compatibility with your existing system, ensuring seamless integration and performance that meets or exceeds your operational demands.

Below is a summary of the core specifications and the advantages of our matching solution:

| Your Key Requirement | Our Solution & Advantages |

|---|---|

| Precise Compatibility | Full OEM Compatibility: Guaranteed to match the exact dimensions and construction of your current CBD-60-B6GP-C000578-001 belt, allowing for perfect splicing and seamless replacement. |

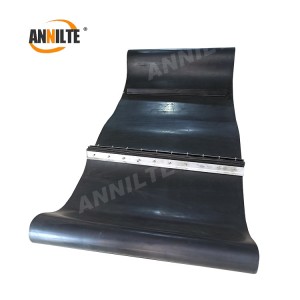

| Superior Durability & Quality | 1. Premium Surface: Features a smooth, flawless cover, free from waves, pores, or cracks, minimizing material adhesion and wear. 2. Reinforced Edge: Molded edge construction with full rubber encapsulation prevents fabric exposure, effectively resisting edge damage and delamination for extended service life. |

| Clear Traceability | Compliant Marking: Permanent markings—including our logo, manufacturing date, and unique batch number—are embossed at intervals of 50-100 meters as specified, ensuring full quality traceability. |

| Robust Load Capacity | Built for Heavy Duty: Reinforced belt construction fully supports your high-capacity requirement of 1,700 TPH. - Design Load: 108.24 kg/m (includes 10% safety margin) - Max. Lump Size: 50 mm - Surge Angle: 25° |

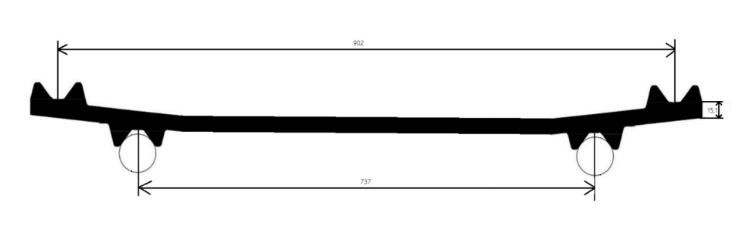

| Core Physical Specifications | Precise Replication, Stable Quality: - Length: 160 meters per roll - Carcass Thickness: 15.1 mm (excluding guide strip) - Guide Strip: 41 mm - Top/Bottom Cover: 4 mm / 3 mm (abrasion-resistant compound) - Belt Weight: 22 kg/m ±5% (strictly controlled) |

| Easy Installation & Maintenance | Pre-fitted Efficient Splice: We can pre-install Flexco F14 fasteners and SC6-950 hinge pins on both ends as per your request, significantly reducing field installation time and labor costs. |

| Extreme Environment Assurance | Wide Temperature Range: Utilizes a special low-temperature resistant rubber compound, ensuring belt flexibility and performance in extreme conditions from -38°C to +38°C, guaranteed for cold-weather operation. |

Our Commitment:

We are providing more than just a belt that meets specifications. We offer a total solution designed to ensure the continuous, efficient, and reliable operation of your equipment. We understand the critical demands of wollastonite handling on belt abrasion resistance and splice reliability, which are fully addressed in this proposal.

Our Product Advantages

- Superior Rubber Compound: We utilize a proprietary blend of high-quality, abrasion-resistant rubber for the top cover. This compound is rigorously tested to have an outstanding abrasion loss value, ensuring it lasts significantly longer than conventional belts.

- Reinforced Carcass Design: Whether you need multi-ply fabric or rugged steel cord construction, our belts feature a robust carcass designed to maintain tensile strength and impact resistance, even under heavy loads of sharp-edged wollastonite.

- Optimal Cover Thickness: We offer customizable top cover thickness to match your specific material lump size and fall height, providing an extra layer of protection where you need it most.

- Excellent Rip & Tear Resistance: Beyond abrasion, our belts are formulated to resist gouging and tearing, common issues in transfer points and chutes.

Applicable Scenarios

Annilte Conveyor Belts are ideal for all stages of wollastonite handling:

- Primary Mining & Crushing

- Screening and Sorting Plants

- Bagging and Loading Facilities

- Transfer Points between Conveyors

Quality Assurance Stability of Supply

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

As a leading Chinese conveyor belt manufacturer with 17 years of industry experience, Annilte is proud to hold both ISO quality management certification and the RoHS environmental directive. Our manufacturing facilities meet “Green Factory” standards, and we are also an internationally recognized SGS Gold Supplier.

We offer a comprehensive range of customizable belt solutions under our own brand "ANNILTE", designed to meet diverse industrial needs.

Should you require further information about our products or capabilities, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/