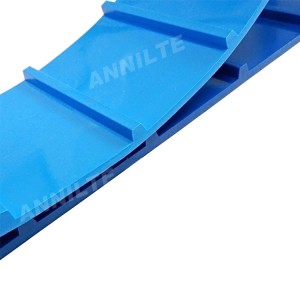

Annilte Wool felt belt for baguette machine

Felt Conveyor Belt Core Functions and Roles

Precise Conveying and Positioning

Felt Conveyor Belt realizes stable conveying of bread blanks through high coefficient of friction, avoiding slipping or piling up to ensure accurate baking position and improve product consistency.

Cushioning and Shock Absorption

The elastic material absorbs the vibration of the equipment and reduces the deformation of the bread billet during the conveying process, ensuring the stability of the shape and structure of the product, which is especially suitable for fragile breads such as bread buns, baguettes, and so on.

Environmental Adaptability

The felt conveyor belt maintains dimensional stability in hot and cold baking environments, avoiding conveying deviations due to thermal expansion and contraction, ensuring efficient operation of the production line.

Our Product Advantages

Extreme Temperature Adaptation: Adopting high temperature modified wool/aramid fiber blend, it can withstand the instantaneous switching of -40°C sharp frozen dough → 260°C baking high temperature (such as steam jet during the baking of omelette), and the material shrinkage rate is <0.3%, which avoids the conveyor belt breakage or runout due to thermal expansion and contraction.

Food-grade safety: FDA/EU 1935/2004 certified, with food-grade water-based PU coating (no PFOA/heavy metals), avoiding the migration of plasticizers, BPA and other harmful substances that may be released by traditional rubber conveyor belts to the surface of bread.

Abrasion resistance increased by 300%: Through fiber cross weaving + nano level infiltration process, the surface hardness of the conveyor belt reaches 75D Shore (ordinary felt belts are only 60D Shore), and the abrasion resistance life is up to 2,000 hours (traditional conveyor belts are about 600 hours) when conveying hard breads (e.g. baguettes, lye breads).

Applicable Scenarios

Bread Production Line

From mixing, fermentation to baking, the felt conveyor belt undertakes the continuous transfer of bread blanks, and is suitable for tunnel ovens, rotary ovens and other equipment to enhance the level of automation.

Pastry & Bakery Processing

Its anti-stick properties are suitable for cake rolls, doughnuts and other products that are prone to sticking, and together with the anti-static coating, it can reduce material residue and improve cleaning efficiency.

Food Packaging Pre-conveyor

In the cooling, slicing and packaging process, the felt conveyor belt protects the surface of the bread from scratches, reduces noise pollution and optimizes the working environment in the workshop.

Quality Assurance Stability of Supply

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/