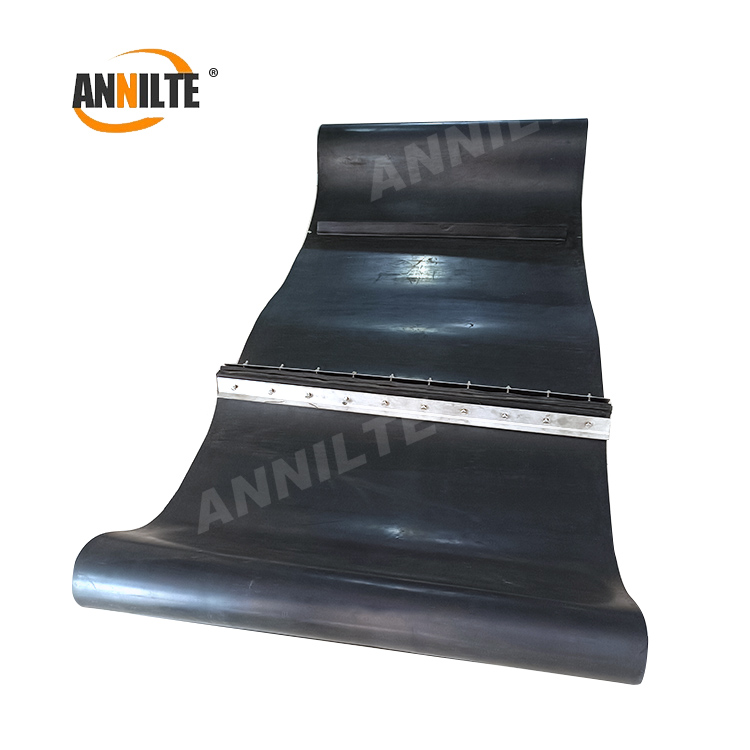

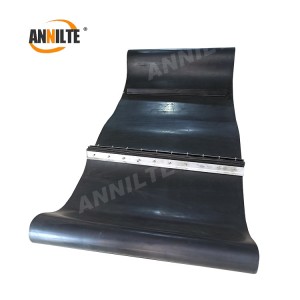

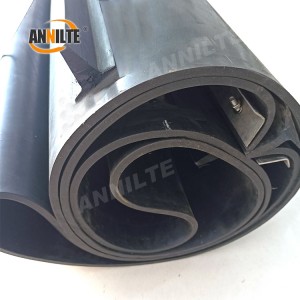

ANNILTE iron remover magnetic separator black baffle endless rubber conveyor belt

Specification Parameters

Bandwidth: Common specifications of the bandwidth are 800mm, 1000mm, 1200mm, 1400mm, 1600mm, etc. Different bandwidths are suitable for different processing capacity and equipment size of the iron remover. For example, the width of 1600mm iron remover belt can meet the needs of larger processing capacity, commonly used in large-scale mining, building materials production line and other scenes.

Length: the length can be customized according to the customer's needs, the common length of 4500mm, 6650mm, 6800mm, 7600mm and so on. Like the length of 7600mm iron remover belt, suitable for long distance material transportation and iron removal conditions.

Thickness: Thickness range is generally 8 - 20mm, different thickness will affect the belt's abrasion resistance, puncture resistance and magnetic field penetration effect. For example, a belt with a thickness of 11 - 11.5mm has good abrasion resistance while ensuring a certain degree of magnetic field penetration, and is suitable for medium-load iron removal operations.

Our Product Advantages

u rubber system tape, does not contain recycled rubber, good toughness, scratch-resistant;

u Surface added Nylonate rubber, anti-friction, wear-resistant, permeability increased by 50%;

u Baffle plate adopts super-conducting vulcanization technology, molded in one piece with the bottom belt, firm and non-dislodging;

u Each belt has at least 7 quality inspections before shipment to ensure that the wear resistance standard is qualified;

u Factory direct sales, support customization;

Applicable Scenarios

Metallurgical Industry

In the process of ore crushing and screening, iron remover belts are used to remove iron chips, nails and other impurities, and protect the subsequent equipment (such as crushers and mills) from damage.

Mining Industry

During the transportation of coal, iron ore and other materials, the iron remover belt can effectively separate the metal impurities mixed into the materials and improve product quality.

Building Materials Industry

In the production process of cement, ceramics, etc., the iron remover belt is used to remove the ferromagnetic impurities in raw materials to avoid affecting the purity and performance of products.

Power industry

In coal-fired power plants, iron remover belts are used to remove iron parts in coal, preventing iron parts from entering coal mills or boilers, which may cause equipment failure or safety accidents.

Quality Assurance Stability of Supply

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/