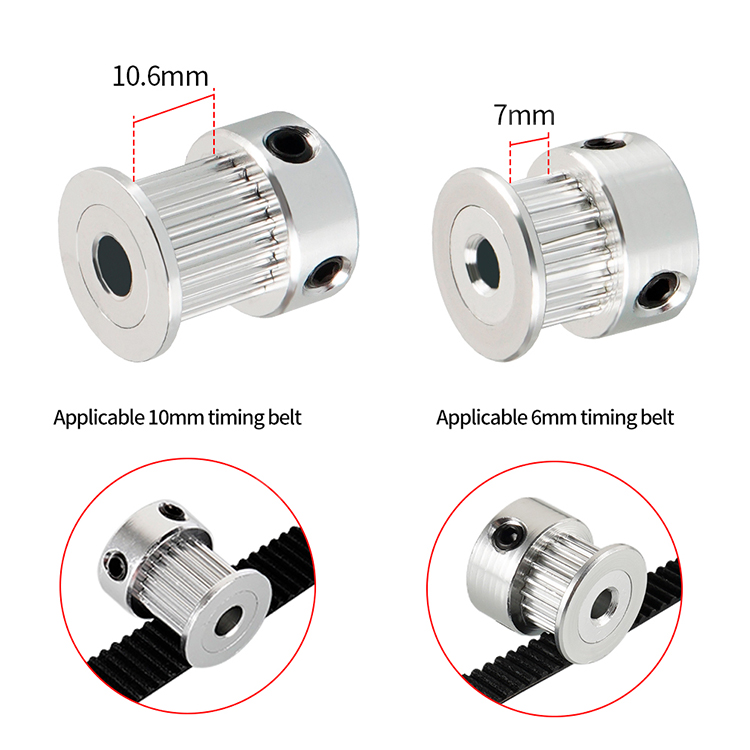

Annilte GT2 Drive Belt Pulleys 16/20 Teeth Timing Pulley

Annilte synchronous wheel

1、Adopt hobbing table, 5 tons of hobbing machine, German CNC equipment, effectively improve the accuracy

2、Focus on non-standard customization can do extra-long, extra-wide synchronous wheels

3、35 engineers, free to provide you with selection and technical support

4、120 technicians, 24 hours response, lightning delivery

5、Synchronous belt and timing pulley are made by the same tool, with high degree of fit, buyers can one-stop purchase.

Annilte undertakes metal trapezoidal and circular tooth timing pulleys, specific models: 3M, 5M, 8M, 14M, 20M, AT5, AT10, G2M, G3M, G5M, H, L, MXL, P2M, P3M, P5M, P8M, S2M, S3M, S4.5M, S5M, S8M, S14M, T5, T10, T20, XH, XL XH, XXH, Y8M, etc.

The synchronous pulleys produced by ANNA can be used both for the synchronous belts of localized equipment and instead of imported synchronous pulleys. If you customize the synchronous pulley, please provide the pulley drawing, we can also draw the pulley drawing for you according to the specifications, pulley bore, keyway, width and other dimensions you provide; we can also provide you with services such as mapping the pulley.

|

Custom CNC Machining Parts Service

|

|

|

Quotation

|

According to your drawing(size, material,and required technology, etc)

|

|

Materials

|

Aluminum, Copper, Brass, Stainless Steel, Steel, Iron, Alloy, Titanium etc.

|

|

Surface Treatment

|

Anodizing, Brushing, Galvanized, laser engraving, Silk printing, polishing, Powder coating, etc.

|

|

Tolerance

|

+/- 0.005mm-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form

|

|

Processing

|

CNC Turning, Milling, Drilling, Hobbing, Polishing, Bushing, Surface Treatment etc.

|

|

Drawing Formats

|

Solid Works, Pro/Engineer, UG, AutoCAD(DXF, DWG), PDF, TIF etc.

|