Felt belts for cutting machines should have the following characteristics:

Abrasion resistance and cutting resistance: Cutting machines need to withstand tool friction and material impact for a long time, it is recommended to use high-density wool felt and polyester fiber composite material with a dense fiber structure, tear strength increased by more than 30%, suitable for metal, leather and other hard materials cutting.

Anti-static performance: electronic components or flammable materials cutting, static electricity may lead to product damage or safety hazards. Can choose to add conductive fiber felt material, surface resistance control in 10⁶-10⁹Ω, effectively avoid the accumulation of static electricity.

Temperature range: laser cutting or high temperature hot pressing scenarios, the felt needs to withstand high temperatures of 150-200 ℃. Aramid fiber reinforced felt can maintain dimensional stability at high temperatures to avoid deformation or carbonization.

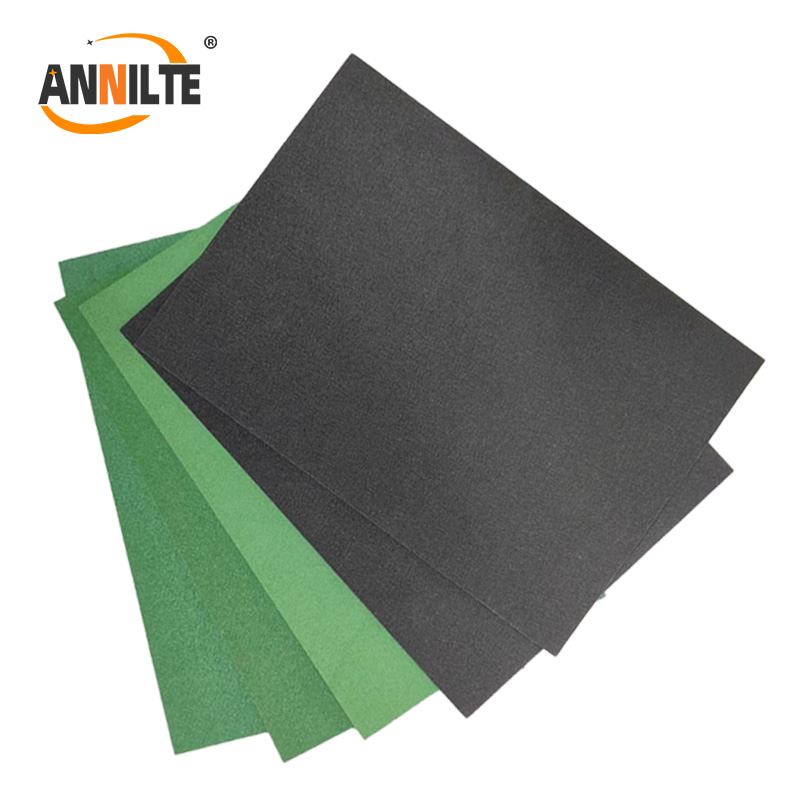

Felt belts for cutting machines developed by Annilte:

Joints: The cutting machine has to be started and stopped at high frequencies and the joints are prone to breakage. It is recommended to use tooth joint or steel buckle joint process, the joint strength can reach more than 90% of the body, and the surface flatness error ≤ 0.5mm, to avoid jamming or runout.

Surface treatment: In order to minimize material sticking, the felt surface can be frosted or coated. For example, the friction coefficient of the felt with silicone coating is reduced by 15%, which is suitable for cutting small materials that are easy to slide.

Noise reduction design: When cutting at high speeds, the noise of the felt rubbing against the material should be kept below 70dB. Felt with honeycomb pore structure can be used to increase sound absorption by 20%, which is suitable for noise-sensitive precision machining shops.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

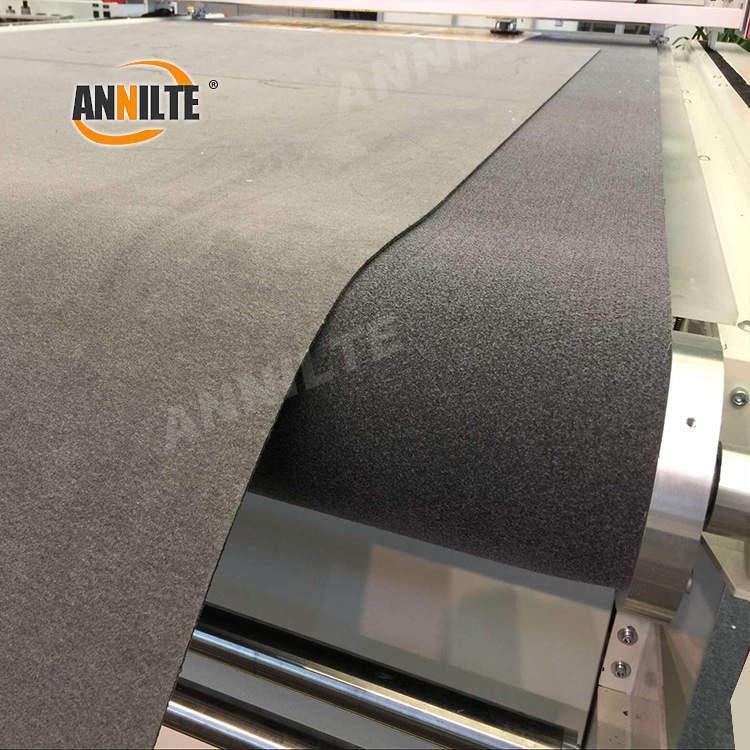

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Apr-27-2025