In the high-speed, precision-driven world of fish processing, every detail matters. The deboning stage is critical —directly impacts your final product quality, yield, and profitability. Yet, a common bottleneck lies in the conveyor system itself. Standard belts can cause slippage, uneven feeding to deboning machines, and are difficult to clean, risking contamination. At Annilte, we understand these challenges. That’s why we engineer specialized Fish Deboning Conveyor Belts designed to optimize this crucial step in your production line.

The Challenges in Fish Deboning Conveyance

- Product Slippage: Fillets and frames sliding on the belt lead to misalignment with deboning machines, causing inefficiency and waste.

- Hygiene Concerns: Porous belt materials can harbor bacteria and bone fragments, compromising food safety and requiring intense cleaning.

- Durability Issues: Constant exposure to moisture, sharp bones, and frequent washdowns can cause premature wear and tear on ordinary belts.

- Yield Loss: Inconsistent belt movement can result in incomplete meat recovery, directly hurting your bottom line.

Why Annilte’s Fish Deboning Conveyor Belt is Your Superior Choice

Annilte belts are not generic; they are purpose-built for the fish processing industry.

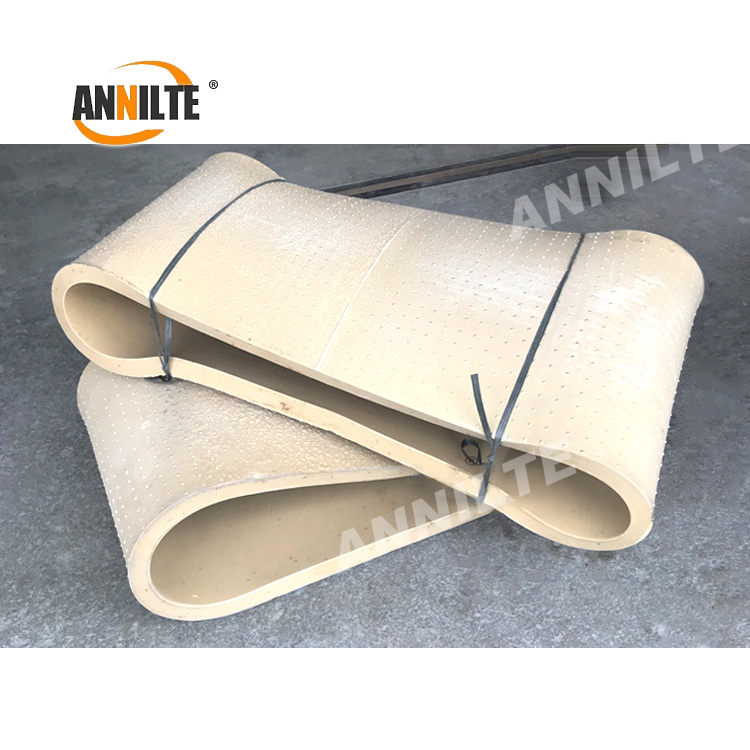

- Enhanced Grip Surface: Our proprietary top cover compounds provide the perfect balance of grip and release. Fillets stay in place for precise machine feeding, while cleaned bones and waste eject easily.

- Hygienic & Easy-Clean Design: We utilize non-porous, FDA-compliant materials that resist bacterial absorption. The smooth surface and sealed edges allow for fast, thorough cleaning during CIP (Clean-in-Place) procedures, ensuring the highest food safety standards.

- Unmatched Durability: Reinforced with high-tensile strength synthetic fabric (like polyester or Aramid) and abrasion-resistant covers, Annilte belts withstand the sharp edges of bones and the rigors of 24/7 operation. This translates to less downtime and lower total cost of ownership.

- Precision Tracking: Stable, consistent belt tracking is vital. Our belts are engineered to run true on your existing equipment, minimizing edge damage and maintenance headaches.

- Customizable Solutions: We offer a range of widths, thicknesses, and cleat profiles (if needed for incline applications) to fit seamlessly into your specific deboning machine setup and layout.

Application Spotlight

Annilte conveyor belts are ideal for automating and improving processes involving:

- Whitefish fillet deboning (e.g., Cod, Pollock, Haddock)

- Salmon frame and belly bone removal

- Pangasius and Tilapia processing lines

- Automated deboning systems for smaller pelagic fish

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

As a leading Chinese conveyor belt manufacturer with 16 years of industry experience, Annilte is proud to hold both ISO quality management certification and ISO 14001 environmental management certification. Our manufacturing facilities meet “Green Factory” standards, and we are also an internationally recognized SGS Gold Supplier.

We offer a comprehensive range of customizable belt solutions under our own brand "ANNILTE", designed to meet diverse industrial needs.

Should you require further information about our products or capabilities, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Jan-12-2026