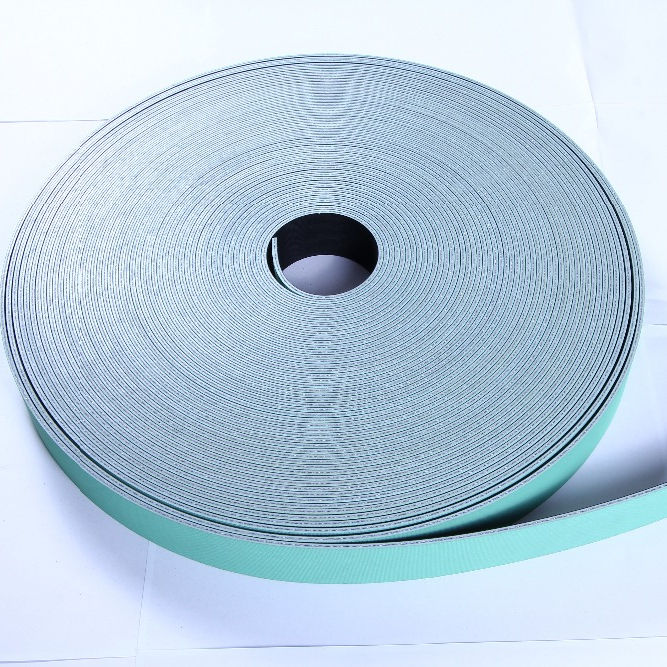

Ukuze kudluliselwe amandla ngendlela eguquguqukayo, umsebenzi ongasizi ngalutho osetshenziswa enkambisweni yokudluliselwa kwamandla, kuba ngcono umphumela wokonga amandla. Ngenqubo yokudluliselwa kwamandla kwebhande elivamile eliyisicaba, isisindo somzimba webhande, indawo egoqwe ngobubanzi besondo kanye namandla okwelulwa aqinile kunquma ukusetshenziswa kwamandla komzimba webhande lapho kwenziwa umsebenzi. Ngakho-ke, ukukhethwa nokucushwa kwebhande lokudlulisela emishinini kuyisici esibalulekile sokwenza ngcono ukonga amandla, futhi ibhande lokudlulisela elinobude obuqinile obungaguquki, umzimba webhande omnene kanye nokungqubuzana kobuso okumaphakathi kuyisinqumo esingcono kakhulu kumakhasimende. Ibhande lokushayela le-polyester lika-Annilte lixazulula kahle izinkinga ezingenhla.

1. I-Polyester enezici zokonga amandla

a) Amandla aphezulu okubamba kanye nokuqina okuzinzile.

Ngokuvamile, uma kuqhathaniswa ne-substrate, amandla okwelula aqinile angu-1% ebhande le-polyester aphezulu ngo-30% kuya ku-50%, okusho ukuthi ibhande alidingi ukulungisa ukungezwani ngokuphindaphindiwe ngemva kokulungisa amandla okungezwani. Ngaphezu kwalokho, ukusebenza kwalo okubushelelezi, ukungezwani okulinganiselwe futhi akulula ukulahlekelwa isivinini, ukuze umthwalo wokuthwala uncishiswe, ngaleyo ndlela kongiwe ukusetshenziswa kukagesi.

b) Izintambo zilula ngesisindo

Ingqimba eqinile yebhande le-polyester iyisakhiwo esikhethekile sendwangu ye-polyester enamandla aphezulu, lapho idluliselwa ngamandla afanayo, ungakhetha ibhande eliyisicaba elincane, ukuze unciphise isikhathi se-inertia kanye namandla e-centrifugal ebhande eliyisicaba, ukuze ukusetshenziswa kwamandla kwalo kuncishiswe futhi ukusetshenziswa kukagesi kugcinwe.

c) Ukuguquguquka okuhle

Ngenxa yokuthi umzimba webhande le-polyester uthambile, umzimba webhande kanye nesondo lebhande kugoqwe kahle, ukucindezeleka kokugoba kuyancipha, ukusebenza kahle kokudlulisa kuyathuthuka futhi ukusetshenziswa kwamandla kuyalondolozwa.

d) Isixhumi siyashesha futhi sinobungani nemvelo

Ijoyinti lisebenzisa ukubopha kwamazinyo okuncibilika okushisayo kwe-thermoplastic elastomer yomzimba, akukho glue efakwayo, futhi ukusebenza akukhawulelwe ohlangothini, ngakho isikhathi sokufakwa siyalondolozwa futhi ukungcola kwemvelo kuyancishiswa.

2. Umphumela wokonga amandla

Ukuhlolwa kokuqhathanisa kwensimu kukhombisa ukuthi isilinganiso sokonga amandla se-polyester strip siphakeme kuno-10% kunese-chip baseband yasekhaya neyakwamanye amazwe.

Umphumela wokonga amandla webhande le-polyester ubaluleke kakhulu, emshinini wentambo yokumboza, izinga lokonga amandla lingafinyelela ku-20%, emshinini omfushane wokusonta kabili wefayibha, izinga lokonga amandla lingaphezu kuka-15%, emshinini wokusonta izikhathi ezingu-310, izinga lokonga amandla liyi-10%. Ngakho-ke, ibhande le-polyester elinokusebenza kwalo okuhle kakhulu kokonga amandla, lisetshenziswe kabanzi njengebhande likadrako kanye nebhande lamandla lemishini emisha esheshayo efana nomshini wokumboza intambo, umshini wokusonta omude kakhulu, umshini wokusonta ojikelezayo kanye nomshini wokusonta kabili.

3. Ukuqhathaniswa kokusebenza kwesakhiwo

Ibhande le-polyester lenziwe ngerabha ekhethekile ye-carboxyl nitrile butadiene yokwenziwa njengento eyinhloko yesendlalelo sokushayela kanye nokungqubuzana, futhi ukusebenza kufana nokwe-substrate.

Ishidi le-thermoplastic polymer elastomer lisetshenziswa njengengqimba yokuguquguquka ehlanganisiwe. Ngemva kokomiswa, izinhlayiya ze-thermoplastic polymer ziyancibilikiswa futhi zikhishwe yi-extruder ukuze zakhe ishidi elinobukhulu obufanayo nobubanzi obungu-1200mm. Futhi ngokusho kobukhulu obuhlukene bokubumba umzimba webhande, ubukhulu obuhlukile obungu-0.3 ~ 1.2mm bemikhiqizo yeshidi. Izinto zinezici zokuqina okuhle kakhulu, ukumelana namafutha, ukumelana nokushisa, ukumelana nokukhathala, ukuguquguquka, amandla adonsela phansi amancane kanye nesisindo esincane, futhi zinezakhiwo ezinhle zokubopha ngengqimba eqinile kanye nerabha.

Isikhathi sokuthunyelwe: Novemba-30-2023