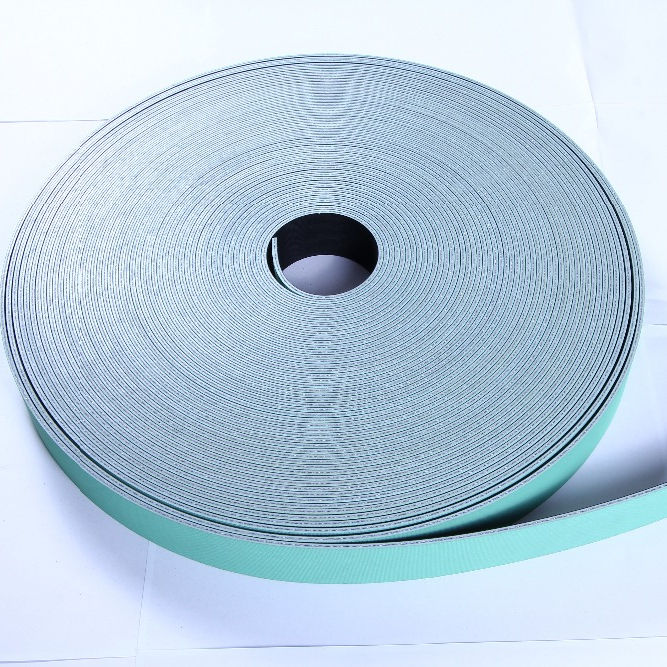

For flexible mechanical transmission, the less useless work consumed in the process of power transmission, the better the energy saving effect. For the process of power transmission of the common flat belt, the weight of the belt body, the area wrapped through the wheel diameter and the fixed extension force determine the energy consumption of the belt body when doing work. Therefore, the selection and configuration of the transmission belt in the equipment is a key factor to optimize energy saving, and the transmission belt with super fixed elongation, gentle belt body and moderate surface friction is the best choice for customers.Annilte’s polyester drive belt solves the above problems well.

1. Polyester with energy-saving characteristics

a) High tensile strength and stable tension.

Usually, compared with the substrate, the 1% fixed stretch strength of the polyester belt is 30% to 50% higher, which means that the belt does not need to adjust the tension repeatedly after adjusting the tension force. In addition, its smooth operation, moderate tension and not easy to lose speed, so that the bearing load is relatively reduced, thus saving electricity consumption.

b) The straps are light in weight

The strong layer of the polyester belt is a special structure of high-strength low-elongation polyester fabric, when the same power transmission, you can choose a thinner flat belt, so as to reduce the moment of inertia and centrifugal force of the flat belt, so that its own energy consumption is reduced and electricity consumption is saved.

c) Good flexibility

Because the polyester belt body is soft, the belt body and the belt wheel are well wrapped, the bending stress is reduced, the transmission efficiency is improved and the power consumption is relatively saved.

d) The connector is fast and environmentally friendly

The joint adopts the hot melt tooth bonding of the body thermoplastic elastomer, no adhesive is applied, and the operation is not limited in the direction, so the installation time is saved and the environmental pollution is reduced.

2. Power saving effect

Field comparison test shows that the average power saving rate of polyester strip is higher than 10% than that of domestic and foreign chip baseband

The power saving effect of polyester belt is very significant, for the coating yarn machine, the power saving rate can reach 20%, for the short fiber double twisting machine, the power saving rate is more than 15%, for the 310 times twisting machine, the power saving rate is 10%. Therefore, polyester belt with its excellent power saving performance, has been widely used as the dragon belt and power belt of new high-speed equipment such as covering yarn machine, super long spinning machine, rotary spinning machine and double twist machine.

3. Structural performance comparison

The polyester belt is made of special synthetic carboxyl nitrile butadiene rubber as the main material of the driving and friction layer, and the performance is the same as that of the substrate.

The thermoplastic polymer elastomer sheet is used as the composite transition layer. After drying, the thermoplastic polymer particles are melted and extruded by the extruder to form the sheet with uniform thickness and width of 1200mm. And according to the different thickness of the belt body molding 0.3 ~ 1.2mm different thickness of sheet products. The material has the characteristics of excellent elasticity, oil resistance, temperature resistance, fatigue resistance, flexibility, small specific gravity and light weight, and has good bonding properties with strong layer and rubber.

Post time: Nov-30-2023