A mention of plane high-speed drive belt, people will first think of sheet-based belt, it is the most widely used industrial belt plane drive belt belt, but in recent years, a kind of transmission belt called “polyester belt” is raging, and gradually squeeze the survival space of sheet-based belt. This article focuses on the difference between chip-based belts and polyester belts, to help you choose a more suitable for their industry products.

1, raw materials

From the raw material point of view, the middle of the sheet base belt is a nylon sheet base to serve as a strong layer, while the surface covered with rubber, cowhide, fiber cloth and other different materials to cope with different use scenarios.

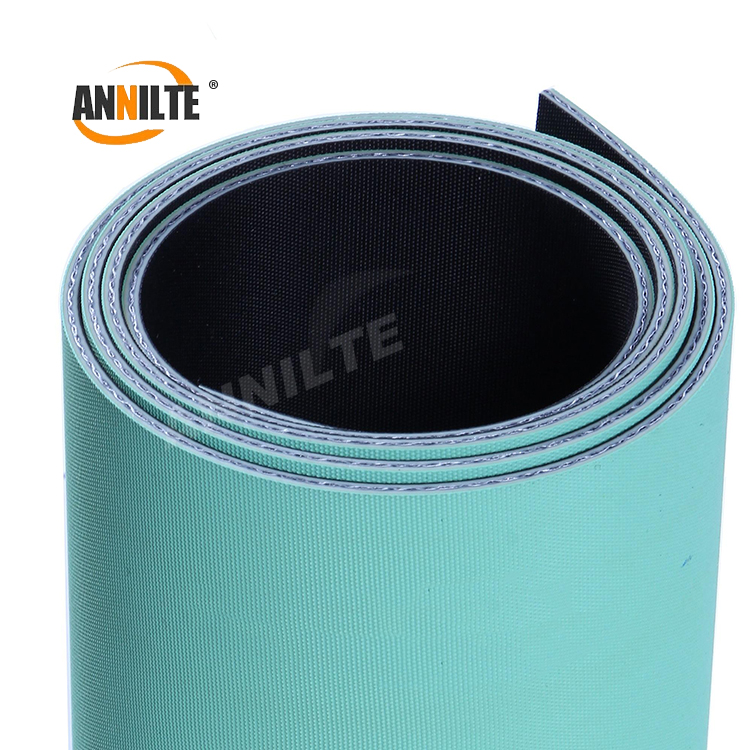

Polyester belts are made of special synthetic carboxyl nitrile rubber as the driving and friction layer, thermoplastic polymer elastomer as the composite transition layer, and high tensile polyester fabric as the strong backbone layer.

2, production process

From the point of view of the production process, the sheet base belt bonding method is to use the adhesive to connect the two sheet base belts together, and this adhesive is usually a special glue, which can be cured quickly at high temperature to form a strong connection.

The polyester belt adopts a tooth-shaped joint, first layered and then toothed, fused together after high temperature vulcanization, the bonded joint part of the force is uniform, and the thickness of the joint is the same as the thickness of the belt.

3、Performance

From the performance point of view, the sheet-based belt has the advantages of strong electrical conductivity, strong anti-interference ability, light weight, strong tensile force, resistance to flexing, high efficiency, low noise, fatigue resistance, good abrasion resistance, long service life and so on. But the shortcomings of sheet-based tape are also obvious such as high elongation, not environmentally friendly.

Polyester belt overcomes the shortcomings of high elongation rate and non-environmental protection of the sheet-based belt, and has the advantages of high fixed tensile strength, stable tension, light weight of the belt body, good softness and flexibility, quick and environmentally friendly joints, high strength, strong corrosion resistance, low maintenance costs, etc., the only drawback is the relatively high cost.

4、Application Scenario

From the point of view of application scenarios, the use of chip-based tape is relatively single, mainly used in the electronics industry, for the production of light bars, liquid crystal displays and other electronic products. Polyester tape has a wide range of uses, can be used in textile, paper, building materials, chemical industry, railroad, electric power, communications and other fields.

Undoubtedly, the birth of polyester belt on the chip-based belt said to be a change in the industry, but taking into account the chip-based belt and polyester belt in the raw materials, production process, performance and application scenarios are different, we need to choose more suitable for their own industry characteristics and specific use of the environment of the drive belt.

Annilte is a manufacturer with 20 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We customize many kinds of belts .We have our own brand “ANNILTE”

If you have any questions about the conveyor belt, please get in touch with us!

Phone /WhatsApp/wechat : +86 18560196101

E-mail: 391886440@qq.com

wechat:+86 18560102292

website:https://www.annilte.net/

Post time: Dec-25-2023