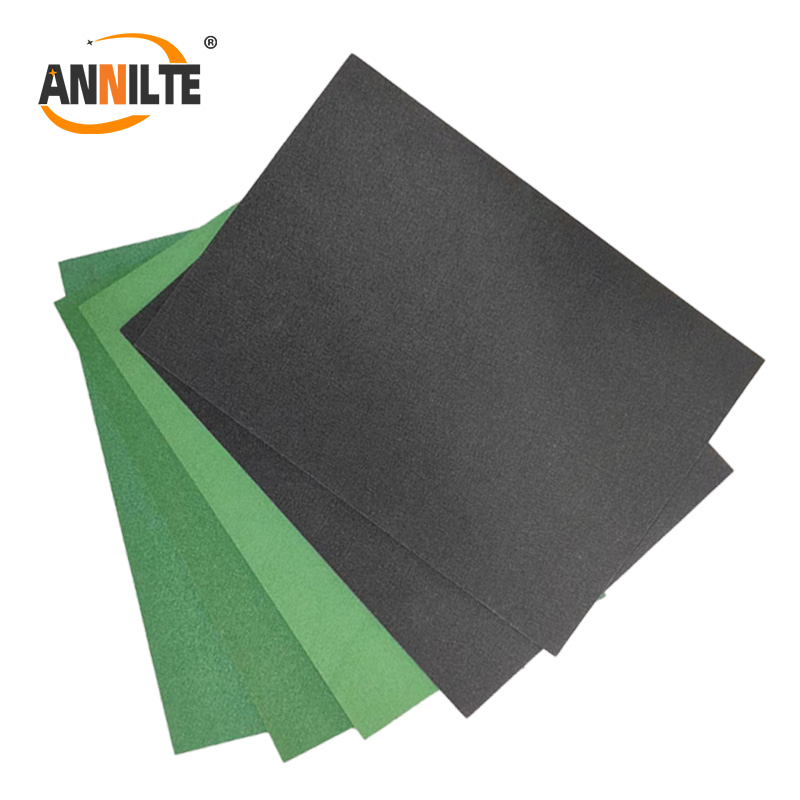

In laser cutting, plasma cutting, or blade cutting applications, are you troubled by material back scratches, incomplete cuts, or wear on your equipment surfaces? What you need isn't just a conveyor belt—it's a precision solution. Today, we'll explore how the Green 1.6mm Felt Conveyor Belt becomes your secret weapon for boosting cutting quality and efficiency.

Five Core Advantages of the Green 1.6mm Felt Conveyor Belt

Our 1.6mm green felt conveyor belt is engineered for demanding industrial environments, offering distinct advantages:

Exceptional Protection

Scratch Resistance: The dense, soft, and elastic felt surface provides perfect cushioning for material backsides (e.g., acrylic, sheet metal, composites, glass), completely eliminating scratches and indentations during cutting and transport.

Anti-Reflection: The specialized green surface effectively absorbs laser beams (particularly CO2 lasers), preventing laser reflection damage to optical lenses or the material itself, ensuring cutting safety and quality.

Unparalleled Cutting Performance

Clean Cuts: Felt fibers help support material edges during cutting, minimizing molten spatter and edge burrs. This ensures clean, smooth cuts with a “one-pass” finish.

Excellent Air Permeability: During laser cutting, the felt's microporous structure allows auxiliary gases (like nitrogen or oxygen) to penetrate uniformly, effectively blowing away molten material to enhance cutting speed and precision.

Durable, Stable, and Reliable

High Temperature Resistance: Withstands the intense heat of laser cutting and sparks from plasma cutting without melting or deforming, ensuring a long service life.

Tensile Strength: The robust base fabric provides excellent dimensional stability, ensuring the conveyor belt does not overstretch or misalign during prolonged use.

Easy Installation and Maintenance

Flexible design allows effortless cutting and fitting to equipment dimensions. Surface dust and debris can be easily removed with a vacuum cleaner for straightforward maintenance.

Which Industries and Equipment Does It Suit?

Signage: Cutting acrylic, dual-color boards, PVC letters

Sheet Metal Fabrication: Laser/plasma cutting of thin steel sheets, stainless steel sheets, copper/aluminum sheets

Furniture Manufacturing: Precision cutting of wood veneers, decorative panels, composite boards

Textiles & Composites: Cutting of carbon fiber, fiberglass, leather

Electronics & Appliances: Die-cutting of insulating materials, silicone gaskets

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Nov-18-2025