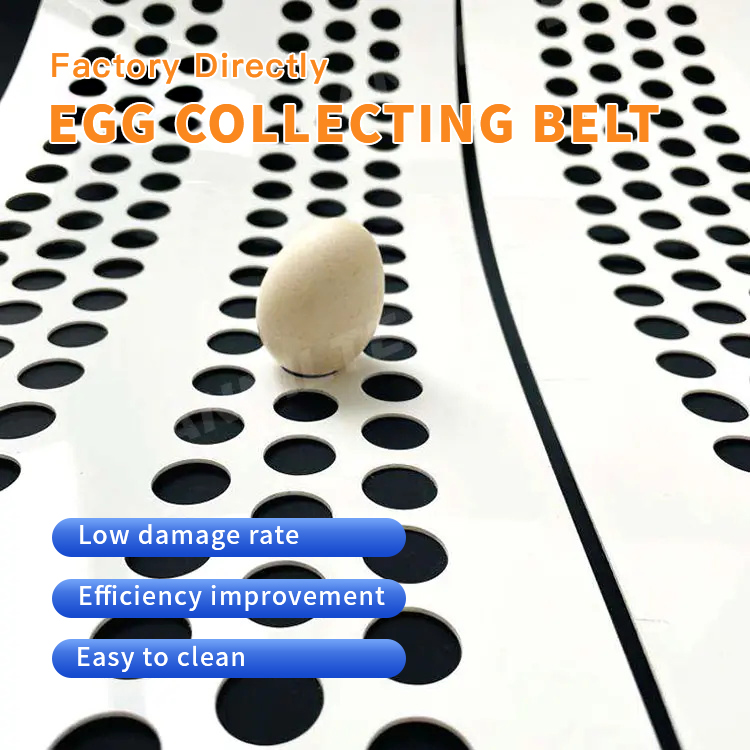

A perforated egg conveyor belt is a specialized type of conveyor belt made from stainless steel wire mesh or plastic, featuring a uniform pattern of small holes or perforations. Its primary purpose is to gently and efficiently transport eggs through various stages of processing (like washing, drying, inspection, and grading) while allowing air, water, and debris to pass through.

1. Design and Materials

Material: Most are made from food-grade stainless steel (e.g., AISI 304 or 316) due to its durability, corrosion resistance, and ease of cleaning. Some systems use FDA-approved plastic or polymer belts for certain lighter-duty applications.

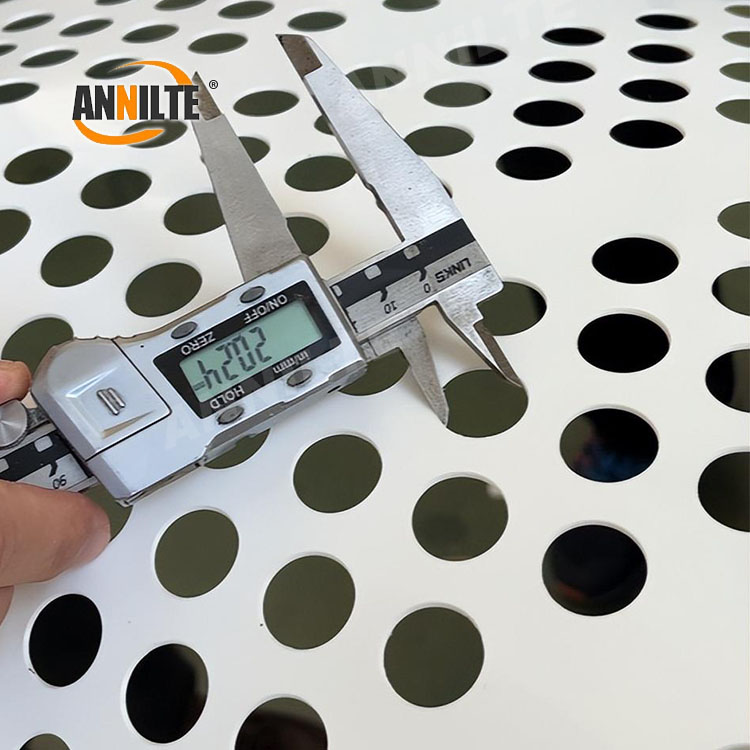

Construction: The belts are woven or fabricated into a grid or mesh pattern. The "perforations" are the open spaces in this mesh.

Surface: The surface is smooth and flat to prevent eggs from rocking or tipping over. The wires are often coated with a soft, non-marking plastic like PVC or nylon to cushion the eggs and prevent shell damage.

2. Key Purposes and Functions

The perforations are not just a design choice; they are critical to the egg processing workflow:

Drainage: This is the most important function. After eggs are washed, the belt carries them through a rinsing and drying stage. The perforations allow water to drain away completely and quickly, preventing recontamination and ensuring the eggs are dry for packaging.

Air Flow: The holes enable hot air to circulate around the eggs during the drying process, making it much more efficient and uniform.

Cleaning and Sanitation: The open mesh design allows for easy cleaning. Spray nozzles can blast water and sanitizing solutions through the belt from both above and below to remove any debris, manure, or broken egg material, maintaining high hygiene standards.

Gentle Handling: The combination of a flat, cushioned surface and the flexibility of the mesh allows for a gentler ride than a solid belt, reducing the risk of cracks and breaks.

Inspection: On grading and inspection lines, the perforated design allows light to pass through from below, making it easier for workers or automated vision systems to detect hairline cracks, blood spots, or other internal defects (through candling).

3. Common Applications

You will find these belts in every major stage of an egg processing plant:

Washing: Transports eggs through the washer.

Drying: Moves eggs through high-velocity air dryers.

Candling & Inspection: Carries eggs under bright lights for quality checks.

Grading & Sorting: Transports eggs to machines that sort them by weight.

Packaging: Feeds eggs to the packing machines that place them into cartons or trays.

4. Advantages Over Solid Belts

Improved Hygiene: Prevents the buildup of moisture and organic matter.

Higher Efficiency: Faster drying and cleaning times.

Reduced Breakage: Gentle handling and a stable surface.

Versatility: Suitable for both "wet" and "dry" sections of the processing line.

Durability: Resistant to rust, corrosion, and wear from constant washing.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Sep-08-2025