In today's high-speed industrial production, cutting processes rank among the most equipment-intensive operations. As a core component, conveyor belts endure constant challenges from sharp materials, repeated impacts, and continuous friction. Are you facing these issues?

Frequent surface scratches and tears leading to premature belt failure?

Production disruptions caused by downtime for repairs?

Eroding profits from constant belt replacement costs?

If the answer is yes, what you need isn't an ordinary conveyor belt—it's a specialized solution engineered for demanding cutting environments: ultra-high abrasion and cut-resistant polyurethane (PU) conveyor belts.

A qualified cutter conveyor belt must possess three core characteristics:

4 Exceptional cut resistance and tear resistance

4 Extremely high abrasion resistance

4 Outstanding dimensional stability

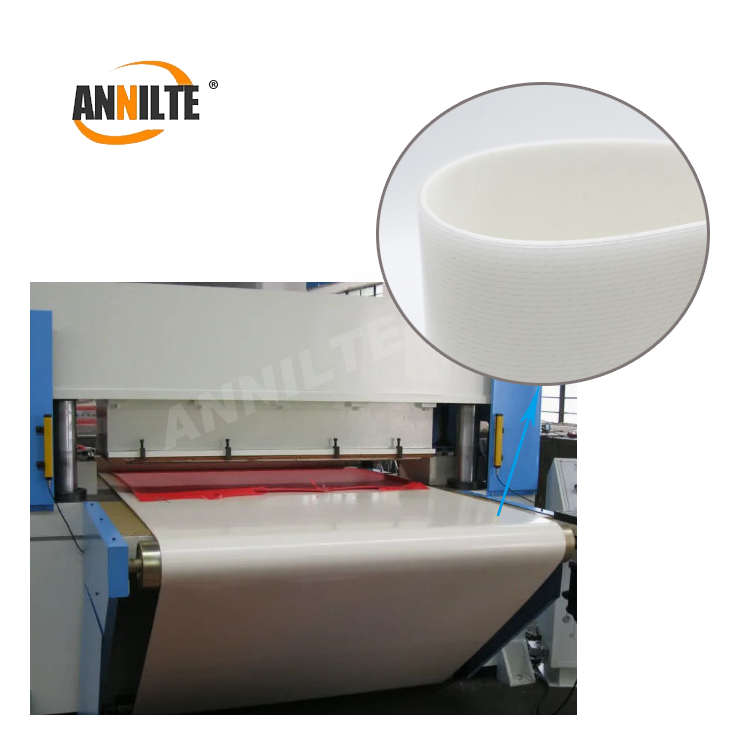

ANNILTE Cut-Resistant PU Conveyor Belt: Engineered for Ultimate Protection

Annilte's high-strength PU conveyor belts, developed through deep understanding of industrial cutting demands, deliver precisely what you seek. Manufactured with specialized formulations and processes, our products excel in critical performance areas:

Indestructible Cut-Resistant Surface: Utilizing high-toughness polyurethane material, it effectively resists cutting and puncturing from sharp materials and debris, significantly extending belt lifespan.

Exceptional Wear Resistance and Durability: Maintains surface integrity even under high-speed, heavy-load friction conditions. Its abrasion resistance is several times that of standard PVC belts, substantially reducing spare part costs and replacement labor.

Superior Dimensional Stability: Resists stretching and deformation, ensuring precise material handling and stable production line operation. Ideal for high-precision automated cutting equipment.

Easy to Clean and Maintain: The dense surface resists dirt accumulation, allowing for effortless removal of debris and dust. This keeps the work environment tidy and minimizes maintenance time.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Nov-06-2025