Just before the National Day holiday, while most were preparing for the break, Shandong AnNai Conveyor Belt Company welcomed a special guest—a Russian client who had traveled thousands of miles. Driven by a commitment to quality, he came specifically for a factory inspection and to gain an in-depth understanding of the technology and quality of our vacuum filter belts.

This cross-border encounter was more than a business discussion; it was a meeting of aligned corporate values.

At Shandong AnNai's headquarters, General Manager Xiu Xueyi personally received the distinguished guest. Through detailed exchanges, the client learned about Annilte's corporate culture and development history, deeply rooted in Confucian principles. He was visibly impressed, frequently nodding in approval, as our core values of "Virtue, Responsibility, Execution, Discipline, and Growth" and our mission "to enhance brand value with professional service and become the most trusted global enterprise in conveyor belts" were explained. It was in these nuanced interactions that the client felt v's warmth and sincerity, building a trust that transcends mere commerce.

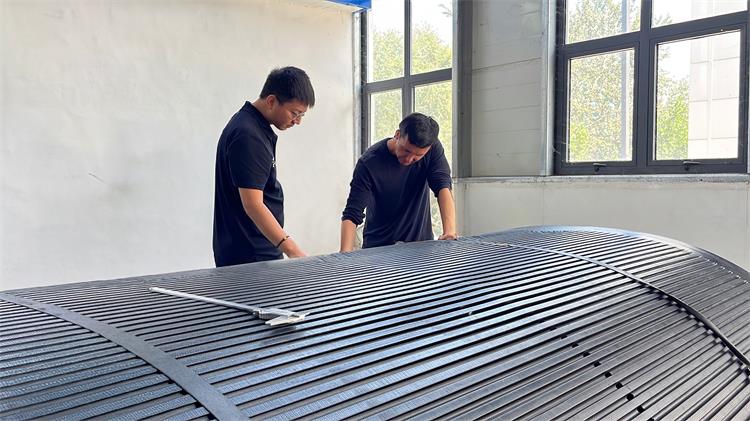

Following the tour of the Jinan office, the client proceeded to our production center. Manager Ma Qiangqiang provided a detailed explanation of the manufacturing process of our vacuum filter belts and shared case studies of our partners. Observing the advanced production equipment and meticulous, the client expressed high recognition of our manufacturing capabilities.

During the inspection, the client carefully examined our vacuum filter belts and remarked, "This is much superior in rubber quality and workmanship to the products we used before." He candidly shared that their previously used filter belts involved manual grooving, which led to uneven groove depth and spacing, potential damage to the fabric layer, and higher costs. In contrast, Annilte's vacuum filter belts are manufactured using imported equipment for one-time vulcanization molding, resulting in uniform groove spacing, consistent depth, and a higher cost-performance ratio.

The client's approval translated into immediate action—he signed a procurement contract for the vacuum filter belts on the spot and expressed his intention to maintain a long-term cooperative relationship. In this moment, we saw more than just a contract; it was the finest affirmation of our years of unwavering commitment to quality and innovation.

As an enterprise specializing in the R&D and production of vacuum filter belts, Annilte consistently prioritizes customer needs and treats product quality as paramount. Our vacuum filter belts are not only wear-resistant and feature sturdy edges but also boast a service life of up to 8 years. We understand the unique requirements of different industries and equipment, which is why we insist on customizing belts based on specific equipment dimensions and filtrate media. We cater to various operational needs, including oil resistance, acid and alkali resistance, high-temperature resistance, and low-temperature resistance. Our vacuum filter belts are widely used for solid-liquid separation in industries such as metallurgy, mining, petrochemical, chemical processing, coal washing, paper manufacturing, fertilizer, food, pharmaceuticals, and environmental protection. They are also applied in gypsum dewatering for flue gas desulfurization and tailings processing.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Oct-01-2025