At Annilte, we specialize in designing and manufacturing durable, application-specific perforated conveyor belts that drive efficiency across industries from food processing to packaging and industrial manufacturing.

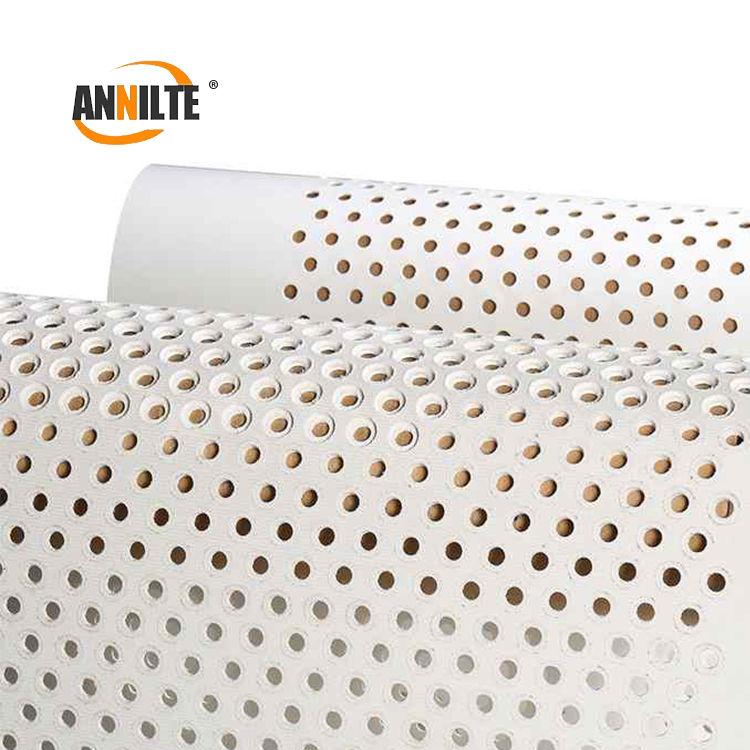

A perforated conveyor belt is a belt intentionally fabricated with a series of holes or apertures in a specific pattern and size. These are not “one-size-fits-all” products. The hole diameter, shape (round, square, slotted), and spacing (pitch) are critically engineered to perform a specific function within your system.

Why Choose a Perforated Belt?

Drainage & Liquid Removal:

- Application: Food processing (washing fruits/vegetables, fish processing), bottling plant rinse sections, wastewater treatment.

- How it works: Allows water, oils, or other liquids to pass through the belt, preventing pooling, improving hygiene, and keeping products dry for the next stage.

- Annilte Solution: We offer belts with optimized hole patterns to ensure fast, complete drainage without compromising belt strength.

Vacuum & Suction Holding:

- Application: Holding lightweight bags, sheets, or products on inclined conveyors; precise positioning in CNC routing or cutting machines; label application.

- How it works: A vacuum chamber under the perforated belt uses suction through the holes to firmly hold items flat and in place, even on steep inclines or at high speeds.

- Annilte Solution: Precision-engineered hole patterns ensure consistent vacuum distribution and reliable hold.

Airflow & Temperature Control:

- Application: Cooling baked goods, chocolates, or packaged products; drying painted or coated items; aerating products.

- How it works: Allows controlled air to pass through the product from above or below, enabling uniform and efficient cooling or drying, reducing process time.

- Annilte Solution: Custom perforation layouts to match your airflow requirements and ensure even exposure.

Sorting & Screening:

- Application: Separating small components or scraps (like in recycling), screening grains, de-dusting.

- How it works: Smaller particles or materials fall through the holes, effectively sorting them from larger items on the conveying line.

- Annilte Solution: Durable belts with wear-resistant edges and precise hole sizing for accurate separation.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 16 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Dec-10-2025