Wollastonite, a valuable industrial mineral known for its brightness and needle-like structure, is notoriously abrasive. In mining, processing, and transportation, this abrasiveness translates into one major operational headache: premature conveyor belt wear. Frequent belt replacements lead to soaring costs, unplanned downtime, and lost productivity.

At Annilte, we understand this challenge intimately. That’s why we’ve engineered our specialized Abrasion Resistant (AR) Rubber Conveyor Belts specifically to withstand the punishing demands of handling abrasive materials like wollastonite.

The High Cost of Wollastonite Abrasion on Standard Belts

Standard conveyor belts simply aren’t cut out for wollastonite. The sharp, hard particles act like sandpaper, causing:

- Rapid Top Cover Wear: Leading to material slippage and reduced efficiency.

- Carcass Damage: Exposing the belt’s internal fabric or steel cords, risking catastrophic failure.

- Increased Energy Consumption: Worn surfaces create more friction.

- Contamination: Belt debris can mix with your high-purity wollastonite product.

Annilte’s Solution: Engineered for Extreme Durability

Our Annilte AR series conveyor belts are built from the ground up to combat abrasion. Here’s what sets them apart:

- Superior Rubber Compound: We utilize a proprietary blend of high-quality, abrasion-resistant rubber for the top cover. This compound is rigorously tested to have an outstanding abrasion loss value, ensuring it lasts significantly longer than conventional belts.

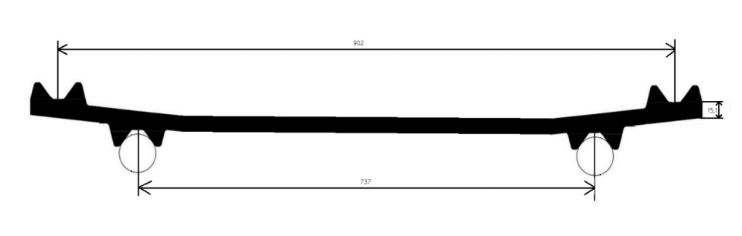

- Reinforced Carcass Design: Whether you need multi-ply fabric or rugged steel cord construction, our belts feature a robust carcass designed to maintain tensile strength and impact resistance, even under heavy loads of sharp-edged wollastonite.

- Optimal Cover Thickness: We offer customizable top cover thickness to match your specific material lump size and fall height, providing an extra layer of protection where you need it most.

- Excellent Rip & Tear Resistance: Beyond abrasion, our belts are formulated to resist gouging and tearing, common issues in transfer points and chutes.

Benefits for Your Wollastonite Operation

- Extended Belt Life: Reduce replacement frequency by 2-3 times, directly lowering your cost per ton conveyed.

- Minimized Unplanned Downtime: Enjoy predictable maintenance schedules and continuous operation.

- Lower Total Cost of Ownership: While the initial investment may be slightly higher, the long-term savings on replacements, labor, and downtime are substantial.

- Improved Safety & Cleanliness: A durable, intact belt reduces the risk of sudden failures and product contamination.

- Enhanced Productivity: Maintain consistent conveying capacity and speed without interruptions.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

As a leading Chinese conveyor belt manufacturer with 17 years of industry experience, Annilte is proud to hold both ISO quality management certification and the RoHS environmental directive. Our manufacturing facilities meet “Green Factory” standards, and we are also an internationally recognized SGS Gold Supplier.

We offer a comprehensive range of customizable belt solutions under our own brand "ANNILTE", designed to meet diverse industrial needs.

Should you require further information about our products or capabilities, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Jan-20-2026