In advanced manufacturing sectors like aerospace, automotive, and sporting goods, the precision cutting of carbon fiber prepreg is a mission-critical process. The choice of conveyor belt directly impacts cut accuracy, material yield, and overall productivity. For engineers and procurement specialists using Gerber cutting systems, Annilte’s specially engineered PU conveyor belts deliver the superior adsorption, cutting resistance, and perfect fit required for flawless prepreg processing.

Why Specialized Conveyor Belts Are Essential for Carbon Fiber Prepreg

Carbon fiber prepreg combines high-strength fibers with a pre-catalyzed resin system. Its exceptional strength-to-weight ratio—often 25% the weight of steel at equivalent strength—makes it indispensable. However, this very strength and its tacky, uncured resin surface present unique challenges during automated cutting:

- Material Shifting: Any movement during cutting ruins part accuracy and wastes expensive material.

- Blade Resistance: Standard belts wear quickly from continuous blade penetration, causing downtime.

- Equipment Compatibility: Belts must interface perfectly with precision machinery like Gerber cutting systems to maintain consistent performance.

Annilte’s response is a purpose-built conveyor belt developed specifically for Gerber cutting machines, ensuring optimal processing for carbon fiber prepregs, automotive interiors, technical textiles, and composite materials.

Annilte’s PU Conveyor Belt: Engineered for Cutting-Edge Performance

Our belts are not generic adaptations but are the result of targeted R&D. Here are the core advantages that set them apart:

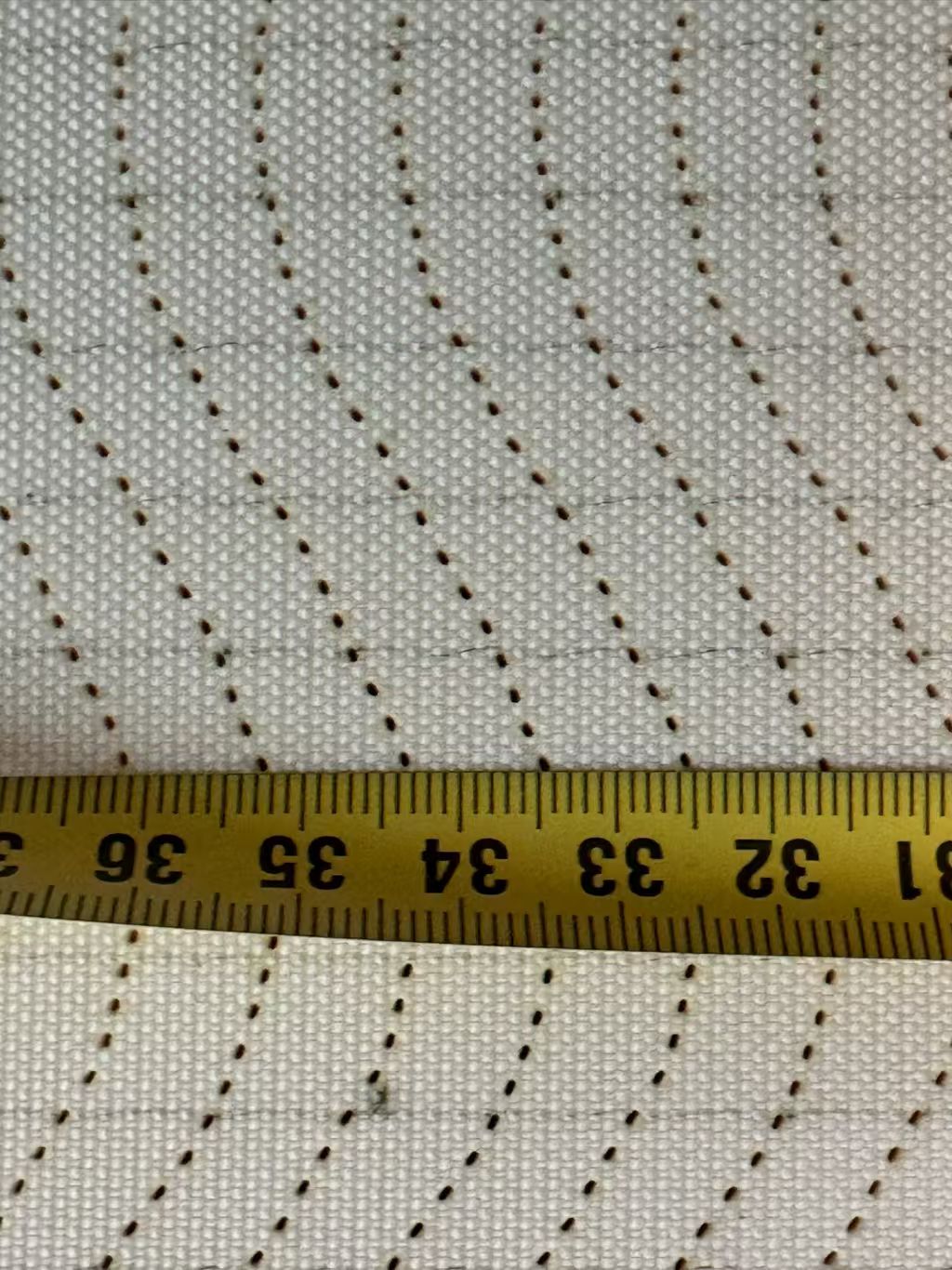

1. Wave Uniform Perforation for Maximum Vacuum Hold-Down

We utilize a proprietary wave uniform cloth perforation pattern. The precise, consistent hole spacing—as tight as approximately 1mm—creates an optimal vacuum distribution across the entire cutting bed. This ensures the prepreg material remains absolutely stationary throughout the cutting cycle, eliminating shift-induced defects.

2. Premium PU Surface with Q-Bouncing Gel for Ultimate Durability

The belt surface is coated with a specialized layer of Q-bouncing gel. This polyurethane-based material offers exceptional:

- Cutting Resistance: It resists penetration damage from reciprocating blades, drastically reducing groove formation.

- Resilience: The gel “bounces back” after blade impact, maintaining a smooth surface.

- Chip-Free Operation: The formulation prevents the generation of debris that could contaminate prepreg or interfere with machine mechanics.

3. Precision Engineering for Gerber System Compatibility

Designed as a direct-fit component for U.S.-manufactured Gerber cutting machines, our belts ensure seamless integration. This perfect fit guarantees consistent tracking, smooth operation, and reliable performance, protecting your valuable equipment investment.

Beyond the Product: The Annilte Assurance

Choosing Annilte means partnering with a dedicated specialist, not just a supplier.

- Focused Expertise: With 15 years of industry experience, our 35-member R&D team has provided customized solutions for over 1,780 industry segments. We understand the nuanced needs of composite material processing.

- Robust Production & Supply: Our 16 fully automated German production lines and strategic raw material stock (over 400,000 sq. meters) enable us to guarantee supply stability. We commit to 24-hour shipment for emergency orders.

- Recognized Quality: As an ISO and SGS-certified manufacturer, our quality controls are internationally recognized. We are a trusted partner to 18 Fortune 500 companies.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 16 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Jan-04-2026