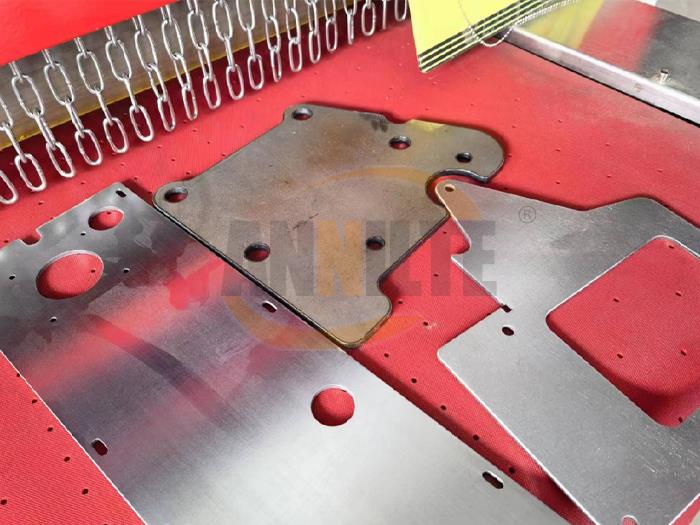

Vacuum metal polishing machine belt is mainly used for flat plate parts, stainless steel plate, carbon steel plate, aluminum plate, copper plate, titanium alloy all kinds of non-ferrous metals, rubber and plastic materials, such as deburring, polishing and grinding, the use of the surface is smoother.

The core types and characteristics of the belt pattern of polishing drawing machine

The belt pattern of polishing drawing machine directly affects the surface treatment effect and equipment efficiency. Mainstream patterns can be divided into the following 5 categories:

1. straight pattern (parallel pattern): the pattern is arranged in a straight line, and the depth is usually 0.5-1.2mm. the advantage is that the friction is uniform, suitable for fine polishing of stainless steel and aluminum alloy, but it is easy to residual scratch.

2. oblique pattern (herringbone pattern): pattern is 30 ° - 45 ° oblique angle, depth of 1.0-1.5 mm, through the cross force to reduce material loss, commonly used in copper rough polishing, efficiency increased by about 20% (Source: Germany ContiTech experimental report).

3. grid pattern: diamond or square raised structure, depth 1.2-2.0mm, mostly used for high hardness metals (such as titanium alloy), can disperse the stress, extend the life of the belt to 1.5 times of the ordinary models.

4. wave pattern: continuous curved design, depth of 0.8-1.5mm, suitable for curved workpiece, can reduce the dead angle of polishing, but wear resistance is poor.

5. Composite grain: combining straight grain and oblique grain, depth 1.0-1.8mm, strong versatility, but higher cost, mostly used for automotive parts and other precision machining.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Jul-22-2025