In industries where precision, cleanliness, and efficient material handling are paramount, the choice of conveyor belt is not just an operational detail—it’s a critical business decision. At Annilte, we engineer Perforated PU Conveyor Belts to meet the highest standards of performance, durability, and application-specific functionality, serving as the backbone for seamless production from food processing to advanced composites.

Why Perforated PU Conveyor Belts Are Essential for Modern Operations

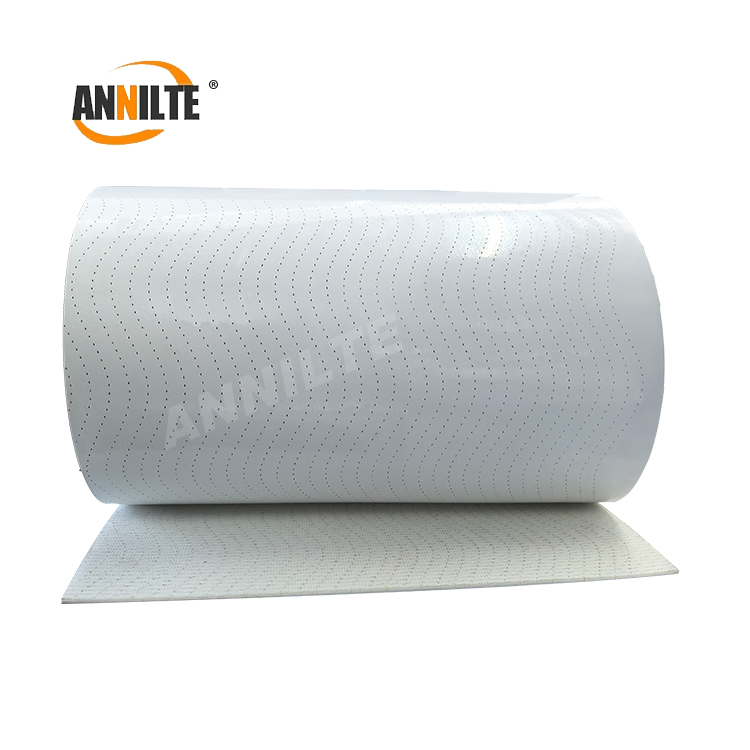

Perforated polyurethane (PU) belts offer a unique combination of properties that solid belts cannot match. The precision perforations allow for crucial functions such as vacuum hold-down, air circulation, liquid drainage, and precise positioning of materials during processes like printing, cutting, or laminating.

For instance, in cutting-edge applications like handling carbon fiber prepregs—as detailed in our solution for Gerber Conveyor Belts for Cutting Carbon Fiber Prepregs—a perforated belt integrated with a vacuum system ensures the delicate material lies perfectly flat and immobile. This prevents shifting during precision cutting, eliminating waste and ensuring flawless quality in aerospace or automotive components.

Key Advantages of Annilte Perforated PU Conveyor Belts

- Superior Material Performance: Our PU belts are wear-resistant, offer excellent tensile strength, and withstand exposure to oils, greases, and many chemicals. They are also FDA-compliant for food contact, making them versatile across sectors.

- Precision Perforation: We offer customized hole patterns (round, square, oval), diameters, and pitches to perfectly match your application’s needs for suction, drainage, or indexing.

- Exceptional Cleanability & Hygiene: The non-porous PU surface and through-holes allow for easy cleaning and prevent bacterial growth, which is vital in food, packaging, and pharmaceutical environments.

- Minimal Maintenance & Long Service Life: Designed for durability under constant tension and movement, our belts reduce downtime and total cost of ownership.

Industries We Serve with Expertise

Annilte’s perforated belts are engineered for diverse challenges:

- Digital Printing & Packaging: Precise registration and hold-down during printing processes.

- Food Processing: Drainage belts for washing, cooling, drying, and freezing operations.

- Nonwovens & Textiles: Handling fabrics during finishing, coating, or laminating.

- Advanced Composites & Technical Materials: Precision cutting and handling of sensitive materials like prepregs, as referenced above.

- Recycling & Sorting: Efficient separation and transportation of materials.

Choose Annilte: Your Partner in Conveyor Solutions

Beyond providing a high-quality product, Annilte partners with you. We offer:

- Custom Engineering: Tailoring belt dimensions, perforations, and properties to your exact system and process.

- Technical Support: From selection to installation and troubleshooting.

- Proven Reliability: A track record of delivering robust solutions for demanding industrial applications.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

As a leading Chinese conveyor belt manufacturer with 17 years of industry experience, Annilte is proud to hold both ISO quality management certification and the RoHS environmental directive. Our manufacturing facilities meet “Green Factory” standards, and we are also an internationally recognized SGS Gold Supplier.

We offer a comprehensive range of customizable belt solutions under our own brand "ANNILTE", designed to meet diverse industrial needs.

Should you require further information about our products or capabilities, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Jan-19-2026