Why choose our Peanut peeling machine belt

1. Precise peeling, half rate up to 98%

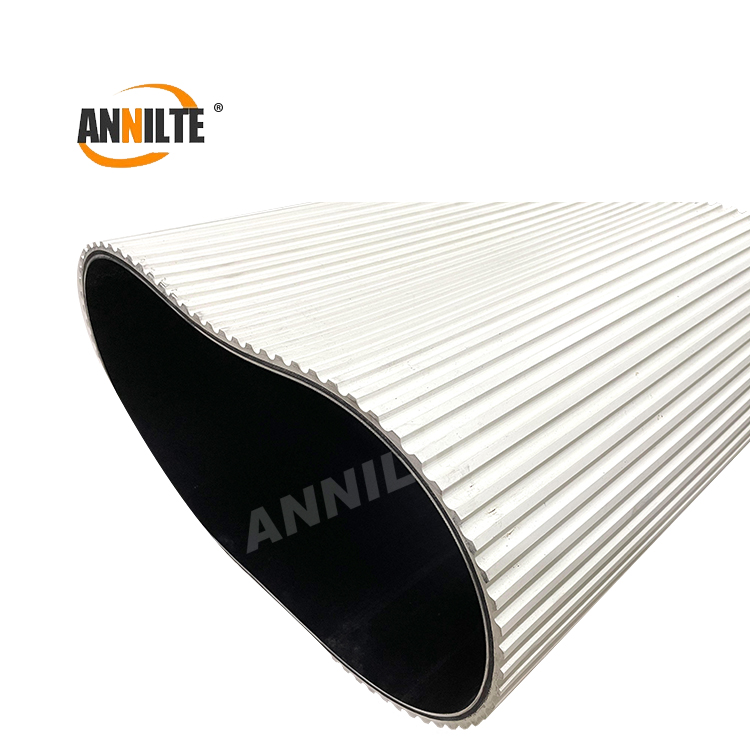

Customized specifications: peripheral length of 1500 × 601 × 13.5mm, tooth spacing Φ6 (small peanuts) / Φ9 (large peanuts), flexible to adapt to different raw materials.

Working principle: original “upper and lower double belt staggered extrusion” technology, long belt ring-shaped bottom, short belt opening fixed above, through the teeth of the precise bite, a complete peeling, halving, de-sprouting, screening and grading, the degree of automation industry-leading.

2. Food-grade safety, zero pollution

Material innovation: food-grade natural rubber + high purity silica, through the FDA food contact certification, to eliminate the risk of plasticizers.

Wear-resistant upgrade: the surface is covered with nano-scale wear-resistant coating, which reduces the rate of slagging by 90% and ensures that the finished peanuts are clean and free of impurities.

3. Flexible extrusion, crushing rate <5%

Formulation optimization: add elastomer buffer layer, rubber hardness precisely regulated, not only to ensure the peeling efficiency, but also to avoid hard rubber extrusion resulting in peanut crushing.

Process upgrading: full numerical control refining process, light inspection of internal air bubbles after vulcanization, yield rate > 99%, to eliminate belt cracking and blistering problems.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: May-16-2025