Why Your Peanut Peeling Machine Needs a Specialized Conveyor Belt

The peanut shelling process demands specific performance from a conveyor belt:

4 Hygiene & Cleanliness: The white rubber surface ensures no contamination, preventing discoloration of peanut kernels and meeting food-grade standards.

4 Anti-Slip & Abrasion Resistance: Hard peanut shells require a belt with excellent grip and superior wear resistance to prevent slippage and premature damage.

4 Flexibility & Precision: The belt must offer stability and flexibility to feed peanuts into the shelling rollers accurately and consistently.

4 Oil & Tear Resistance: It must withstand the natural oils from peanuts and resist potential impacts and tearing.

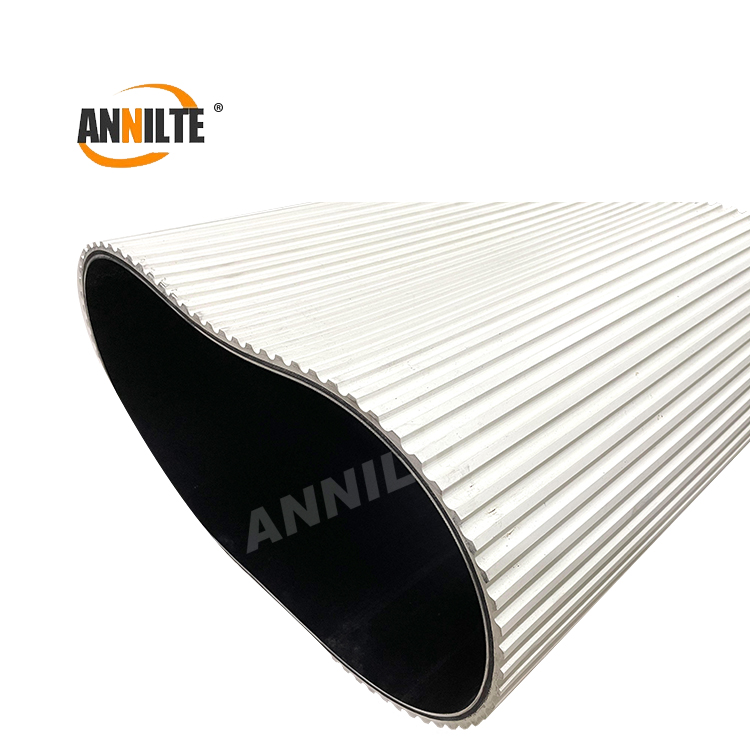

Annilte White Rubber Conveyor Belt: Engineered to Boost Your Peanut Processing Efficiency

At Annilte, we understand these challenges deeply. Our White Rubber Conveyor Belt is meticulously engineered and tested to perfectly match various models of peanut sheller and groundnut peeling machines.

Our Key Product Advantages:

1、Superior Food-Grade Safety: Made with hygienic white rubber compound, it guarantees the purity and safety of your peanut products, making it ideal for food processing applications.

2、Exceptional Durability: Reinforced carcass and a wear-resistant rubber formula significantly extend the belt's service life in harsh operating conditions, reducing replacement frequency and your total cost of ownership.

3、Excellent Anti-Slip Performance: An optimized surface texture provides superior grip, ensuring stable transportation of peanuts without rollback, enabling continuous and efficient operation of your sheller machine.

4、Strong Oil & Aging Resistance: Resists peanut oils and prevents cracking and loss of elasticity caused by prolonged exposure, ensuring long-term performance.

5、Customized Solutions: We provide belts tailored to your machine's exact requirements—width, length, and thickness—for a perfect fit and easy installation.

How Annilte Conveyor Belts Add Value to Your Business

4 Increase Output: Minimize downtime caused by belt failures, keeping your production line running continuously.

4 Reduce Maintenance Costs: A longer operational life means fewer spare part purchases and less frequent manual replacements.

4 Ensure Product Quality: A clean conveying surface protects your peanut kernels from contamination, safeguarding your brand's reputation.

4 Enhance Overall Efficiency: Reliable conveying performance is the foundation for optimizing your entire processing workflow.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 16 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Nov-28-2025