The surface quality of conveyor belts is critical to gypsum board yield rates. Any minor flaw on standard belts will leave an imprint on the board surface during solidification, directly causing defects like indentations and patterns—the primary cause of elevated defect rates. Annilte has innovatively developed high-performance gypsum board conveyor belts, successfully resolving this industry challenge.

In modern architectural decoration, gypsum board has become an indispensable core material for ceilings, partition walls, and various design applications due to its lightweight, fire-resistant, moisture-proof, and easy-to-process properties. Its applications are extremely widespread.

However, gypsum board production demands exceptionally stringent manufacturing processes, particularly during conveying. Surface defects on standard conveyor belts readily cause indentations, patterns, or even structural damage to finished boards, drastically reducing yield rates—a persistent industry pain point for manufacturers.

National standards impose clear and rigorous quality requirements for gypsum boards. Each gypsum board must exhibit a smooth surface, uniform texture, and clean edges. Yet in actual production, conveyor belts—as the key equipment in direct, prolonged contact with the boards—can transfer even the slightest surface imperfections—including textures barely visible to the naked eye—onto the board surface during gypsum slurry forming and curing. This results in a significant increase in defective product rates. This not only leads to material waste and reduced efficiency but also directly impacts corporate profitability and brand reputation.

Addressing this widespread challenge, Annilte leveraged its deep industry expertise and technological accumulation. Through extensive field analysis at multiple gypsum board production sites, systematic root-cause analysis of defect generation, and rigorous testing of over twenty material and process combinations, Annilte successfully developed the Gypsum Board Conveyor Belt. Through multiple technological breakthroughs, this conveyor belt achieves true “mirror-grade” surface quality, completely eliminating defects caused by belt surface issues.

Actual application data shows that after adopting Annilte Gypsum Board Conveyor Belts, customers' production lines have seen an average reduction of over 50% in gypsum board defect rates. Surface smoothness and overall consistency have significantly improved, making it an ideal choice for numerous enterprises seeking cost reduction and efficiency gains.

The core advantages of Annilte Gypsum Board Conveyor Belts are manifested in three key aspects:

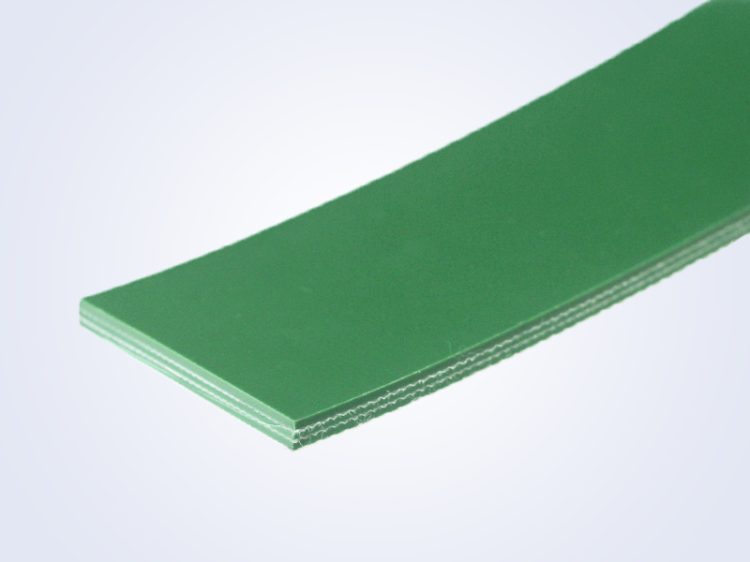

1. Mirror-like Surface Smoothness

Through specialized formulations and precision processing, the belt surface achieves flawless flatness without any micro-textures or imperfections. This ensures gypsum boards remain undamaged during conveyance, substantially boosting product pass rates.

2. Seamless and Secure Joints

Employing German superconductor vulcanization technology achieves high-strength bonding at joints with uniform overall thickness. This prevents issues like joint splitting or fracture, ensuring smooth and stable production.

3. Significantly Extended Service Life

Constructed from virgin rubber without calcium carbonate plasticizers, the belt maintains excellent flexibility even in low-temperature environments. This prevents hardening and brittleness, significantly extending the service cycle and reducing overall operational costs.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Sep-19-2025