In today's resource-conscious world, efficient waste sorting is a critical challenge. An ordinary conveyor belt can become a weak link in a high-value recycling operation, with frequent baffle detachment, poor tracking, and premature wear causing costly downtime. The ANNILTE Intelligent Garbage Sorting Conveyor Belt is engineered from the ground up to solve these exact problems, delivering unmatched durability and precision for material recovery facilities (MRFs), recycling plants, and waste management centers globally.

Why Standard Conveyor Belts Fail in Sorting Applications

Sorting facilities demand more from their conveyor systems. High-volume, high-speed operations involving sharp objects, variable weights, and constant friction push conventional belts to their limits. The common failure points are clear:

- Baffle/Divider Detachment: Critical for separating different material streams, these components often crack and fall off with standard vulcanization, crippling sorting accuracy.

- Belt Tracking Issues: Misaligned or "running" belts cause material spillage, damage to equipment, and require constant manual adjustment, halting productivity.

- Rapid Wear & Tear: Exposure to abrasive materials, chemicals, and moisture quickly degrades standard belts, leading to short lifespans and frequent, costly replacements.

Engineered for Excellence: The ANNILTE Difference

The ANNILTE Intelligent Garbage Sorting Conveyor Belt is not a modified industrial belt; it is a purpose-built solution designed for the rigors of the recycling industry.

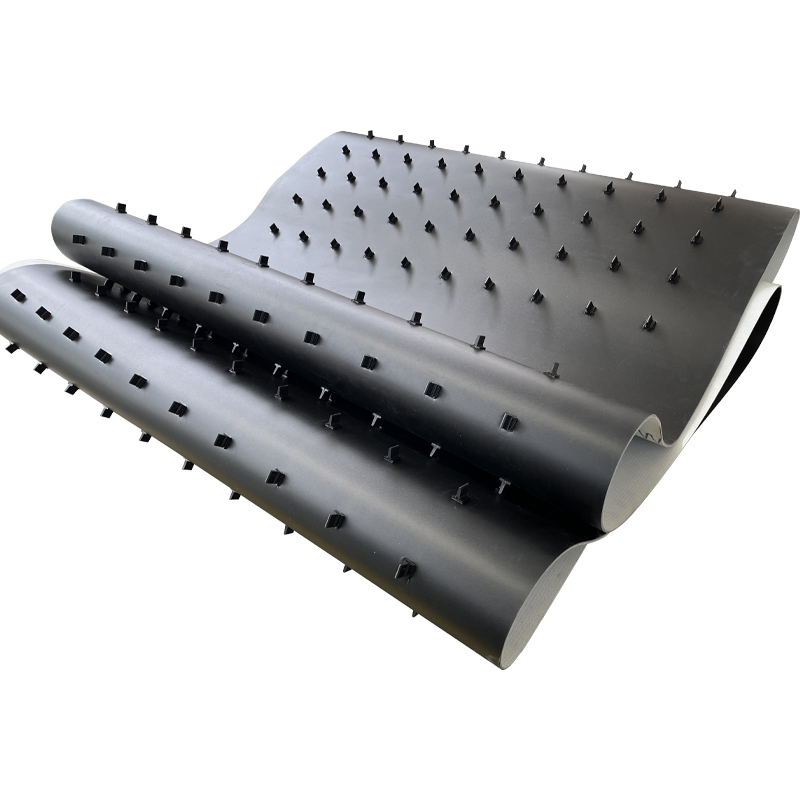

1. Unbreakable Bond: German Superconducting Vulcanization

At the core of our solution is advanced German superconducting vulcanization technology. This process fuses the baffles and guide strips directly into the base belt, creating a single, inseparable unit. The result? A bond so strong it virtually eliminates the problem of cracking and detachment, even under sustained high-speed operation and heavy loads.

2. Precision That Lasts: Anti-Runoff Design & Rigorous Testing

Precision is non-negotiable. We employ infrared positioning and a specialized diagonal cutting process during manufacturing to ensure each belt is dimensionally perfect. This, combined with condition-specific guide strip design, guarantees the belt runs true, reducing turning force and maintaining perfect alignment.

Every belt undergoes a strict tensile test and a real-world on-board test before shipment. We verify that every component performs flawlessly under simulated operational stress, so you receive a product guaranteed to work.

3. Built for the Long Haul: Superior Durability

Durability is engineered into every layer. Our belts are constructed from over 200 specialized raw materials and subjected to more than 300 cycles of chemical corrosion and abrasion testing. This intensive R&D process enhances inter-layer adhesion and wear resistance, extending the service life of an ANNILTE belt by 2 to 3 times compared to ordinary alternatives.

Versatile Applications Across the Recycling Industry

The ANNILTE Intelligent Sorting Belt is the backbone for efficient operations in diverse scenarios:

- Plastics Recycling: Ideal for PET bottle sorting lines, bottle flake cleaning systems, and film recycling equipment.

- Municipal Solid Waste (MSW) Sorting: Efficiently separates recyclables like PP containers, aluminum cans, glass bottles, textiles, and shoes in urban waste processing stations.

- Specialized Waste Streams: Effectively handles construction & demolition (C&D) waste and industrial product sorting.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

As a leading Chinese conveyor belt manufacturer with 17 years of industry experience, Annilte is proud to hold both ISO quality management certification and CE certification. Our manufacturing facilities meet “Green Factory” standards, and we are also an internationally recognized SGS Gold Supplier.

We offer a comprehensive range of customizable belt solutions under our own brand "ANNILTE", designed to meet diverse industrial needs.

Should you require further information about our products or capabilities, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Jan-16-2026