In the leather processing industry, efficiency and precision are paramount. Leather squeezing machines play a critical role in removing excess water and ensuring consistent thickness, but their performance heavily relies on the conveyor belt's quality. At Annilte, we understand the unique challenges faced by tanneries and leather manufacturers. That’s why we’ve engineered a specialized Leather Squeezing Machine Conveyor Belt that delivers unmatched durability, grip, and smooth operation.

Industry Pain Points & How Annilte Solves Them

- Belt Slippage & Inconsistent Pressure: Poor-quality belts often slip, leading to uneven squeezing and wasted materials. Annilte belts feature a high-friction surface that ensures stable movement and consistent pressure.

- Frequent Wear & Tear: Leather processing involves exposure to moisture, chemicals, and mechanical stress. Our belts are made from reinforced materials that resist abrasion, corrosion, and stretching.

- Downtime & Maintenance Costs: Constant belt replacements disrupt production. Annilte belts are built for longevity, reducing downtime and maintenance expenses.

- Hygiene & Contamination Risks: Leather requires clean handling. Our non-porous, easy-to-clean surfaces prevent contamination and meet industry hygiene standards.

Why Choose Annilte for Your Leather Squeezing Needs?

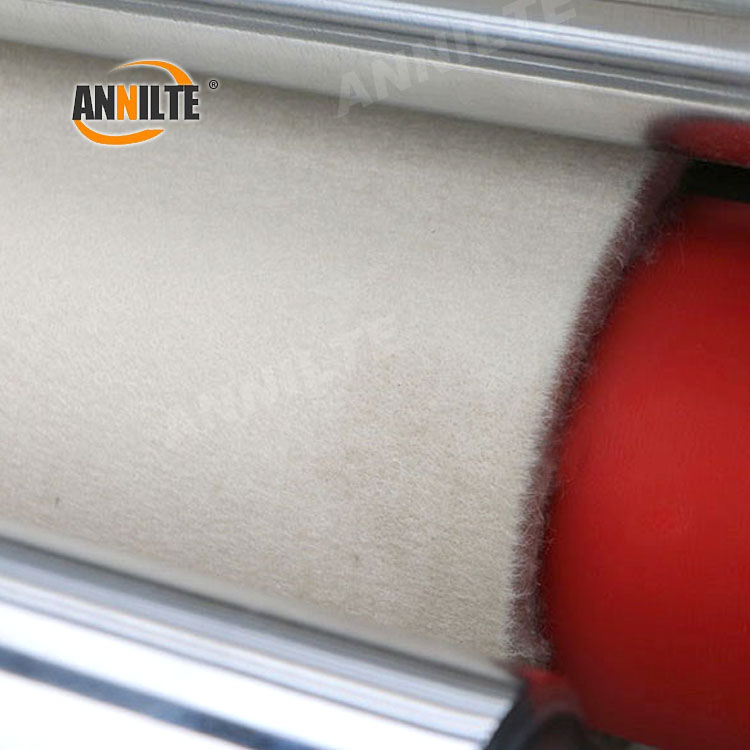

- Superior Material: Made from high-grade synthetic rubber and fabric plies for flexibility and strength.

- Enhanced Grip Texture: Designed to hold leather sheets firmly without damaging the surface.

- Water & Chemical Resistance: Ideal for wet processing stages, ensuring longevity even in harsh environments.

- Customizable Sizes: Available in various widths, lengths, and thicknesses to fit most squeezing machine models.

- Proven Performance: Trusted by tanneries worldwide for reliable, day-in-day-out operation.

Compatible with Leading Leather Processing Brands

Annilte conveyor belts are designed to integrate seamlessly with popular leather squeezing machine brands, including:J. R. Dare & Sons,Krauss-Maffei,Mazzoni,Poletin,Simes

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

As a leading Chinese conveyor belt manufacturer with 17 years of industry experience, Annilte is proud to hold both ISO quality management certification and the RoHS environmental directive. Our manufacturing facilities meet “Green Factory” standards, and we are also an internationally recognized SGS Gold Supplier.

We offer a comprehensive range of customizable belt solutions under our own brand "ANNILTE", designed to meet diverse industrial needs.

Should you require further information about our products or capabilities, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Feb-06-2026