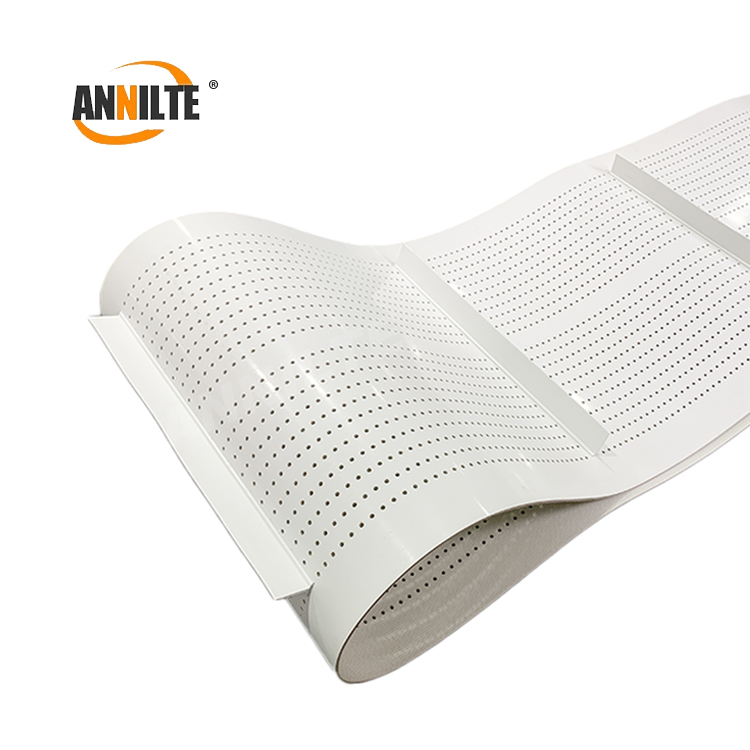

Four Core Advantages of Perforated Conveyor Belts Solve Your Production Pain Points

Exceptional Vacuum Adhesion Capability

Pain Point Solved: Lightweight, thin, and small items (such as paper, labels, film, electronic components) are prone to shifting, slipping, or falling during high-speed conveyance.

Solution: When paired with vacuum pump systems, perforated conveyor belts generate powerful suction to securely anchor products on the belt surface. This ensures precise positioning and stable transport, significantly boosting production efficiency and product yield.

Efficient Liquid and Air Management

Challenge: Residual liquids on product surfaces during washing, cooling, pasteurization, or food processing cannot be promptly removed, hindering subsequent steps.

Solution: Perforated designs allow seamless passage of liquids like water, oil, or coolants, along with hot air, enabling rapid drainage, drying, and cooling. This ensures products remain dry and clean, elevating overall quality.

Precise Screening and Separation Capabilities

Challenge: In agriculture or mining, materials of varying sizes require separation.

Solution: By customizing specific aperture sizes and spacing, the conveyor belt performs preliminary screening and sorting during transport, enabling multi-functional operation and streamlining processes.

Enhanced Grip and Traction

Addressing the challenge: Products tend to slide due to inertia during inclined conveying or in sections requiring frequent starts and stops.

Solution: The edges of the holes provide additional friction, preventing packaging boxes, bagged products, and similar items from slipping during inclined transport, ensuring production safety.

As a professional industrial belt manufacturer, Annilte customizes the most suitable perforated conveyor belt solutions based on your specific equipment model, operating environment (temperature, humidity, load), and process requirements. This ensures perfect compatibility and maximizes performance.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Nov-10-2025