What is a High-Temperature Resistant PTFE Mesh Belt?

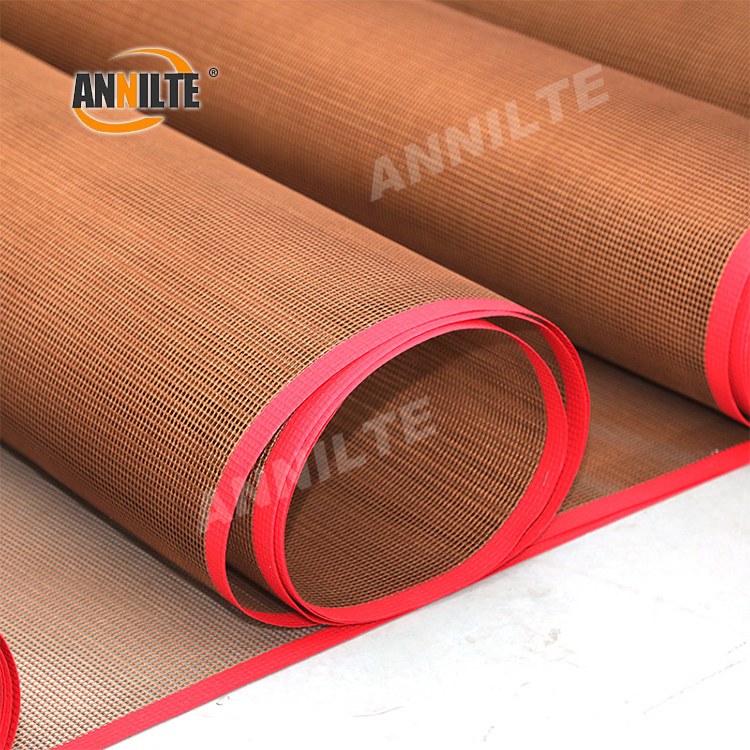

A high-temperature resistant PTFE mesh belt is a mesh conveyor belt woven from glass fiber yarn coated with polytetrafluoroethylene (PTFE). PTFE, commonly known as “Teflon,” is renowned for its exceptional chemical inertness and remarkable temperature resistance. This unique combination enables PTFE mesh belts to operate stably within an extreme temperature range of -70°C to +260°C (even up to 300°C for short durations) without any degradation in performance.

Why does your production line require premium Annilte's high-temperature PTFE mesh belts?

Unparalleled High-Temperature Resistance

Core Advantage: Continuous operating temperatures up to 260°C, perfectly suited for high-heat processes like drying, curing, sintering, and heat sealing.

Customer Benefits: Eliminates belt deformation, cracking, or melting caused by high temperatures, significantly extending service life while reducing downtime and replacement costs.

Exceptional Non-stick Properties & Easy Cleanability

Core Advantage: PTFE surfaces exhibit extremely low surface tension, preventing nearly all viscous substances (e.g., dough, syrup, adhesives, resins) from adhering firmly.

Customer Benefits: Zero residue after product conveyance, drastically reducing cleaning and maintenance time while ensuring product purity—ideal for food, adhesive, and composite industries.

Outstanding Dimensional Stability and Strength

Core Advantage: Utilizes high-strength glass fiber as the base material, featuring extremely low thermal shrinkage. Resists elongation or deformation at high temperatures with minimal belt drift.

Customer Benefit: Ensures smooth, precise conveying, protects delicate products, and enhances production efficiency and product consistency.

Superior Chemical Resistance

Core Advantage: Exhibits excellent resistance to most strong acids, alkalis, and organic solvents.

Customer Benefits: Suitable for harsh environments like chemical processing, dyeing, and electroplating, with minimal belt corrosion damage.

Compliance with Food and Safety Standards

Core Advantage: PTFE material meets international food contact standards including FDA (U.S. Food and Drug Administration), being non-toxic and odorless.

Customer Benefits: Ideal for food baking, frying, freezing, and pharmaceutical drying applications, ensuring final product safety and hygiene.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

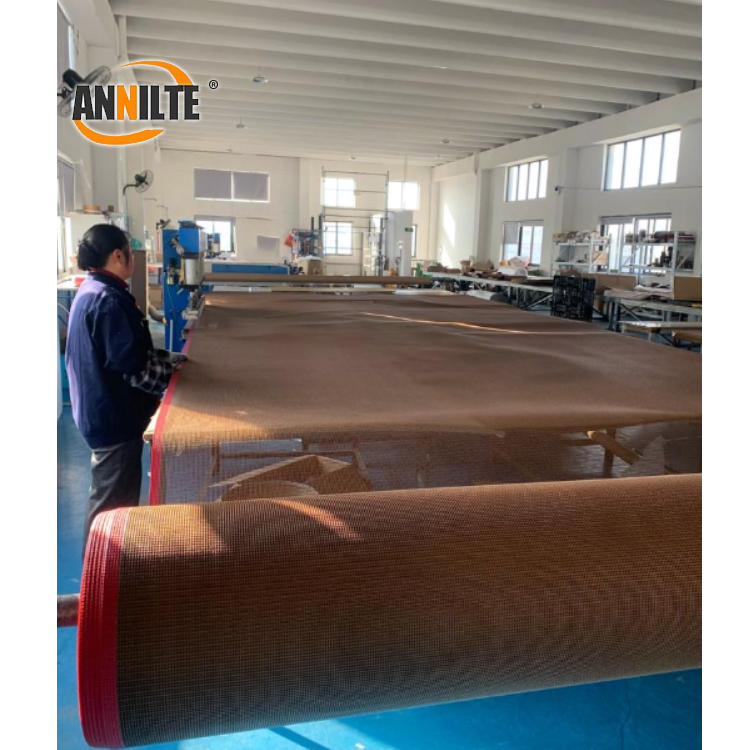

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Nov-03-2025