In the demanding world of leather manufacturing, your press's performance depends heavily on one critical component: the industrial felt. The right felt ensures consistent quality, minimizes downtime, and protects your equipment. At Annilte, we specialize in engineering premium industrial felts specifically designed for the rigorous conditions of leather pressing and finishing.

Why Your Choice of Press Felt Matters:

Poor-quality felt can lead to:

• Uneven leather finishes and inconsistent gloss

• Frequent replacements and production stoppages

• Potential damage to expensive press platens

• Increased long-term operational costs

Annilte's Solution: Engineered for Excellence

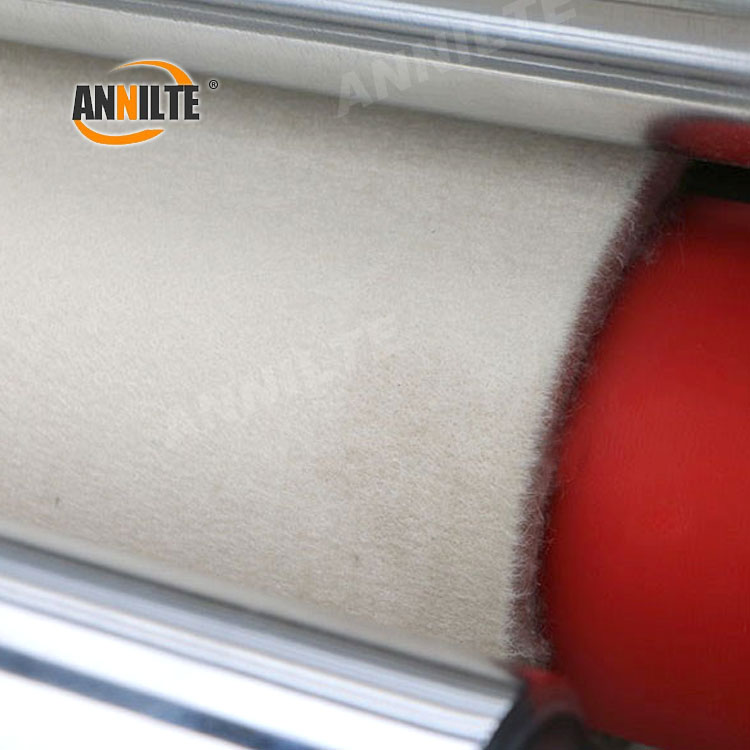

Our industrial felts are manufactured using advanced needle-punch technology and premium materials to deliver:

1. Exceptional Heat Resistance

Designed to maintain structural integrity under continuous operational temperatures, our felts prevent hardening or degradation that can affect finish quality and felt lifespan.

2. Superior Durability & Longevity

High-density construction and abrasion-resistant fibers provide extended service life, reducing replacement frequency and lowering your total cost of ownership.

3. Consistent, High-Quality Results

Uniform density and calibrated resilience ensure even pressure distribution across the entire hide, guaranteeing flawless finishes whether polishing, leveling, or embossing.

4. Perfect Custom Fit

We provide rolls, sheets, or precision-cut pieces tailored to your specific press model and application requirements, ensuring optimal performance and easy installation.

Technical Specifications:

• Materials: Premium synthetic blends or 100% wool options

• Thickness: 3mm to 20mm (customizable)

• Temperature Resistance: Up to 220°C/430°F continuous

• Available in various densities and surface treatments

Applications:

• Hydraulic and platen leather presses

• Leather polishing and leveling machines

• Embossing and finishing equipment

• Replacement felt for all major press brands

Why Choose Annilte?

With years of experience serving the leather industry, we understand the unique challenges of leather finishing. Our technical team can help you select the perfect felt specification for your specific application, press model, and desired finish.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

As a leading Chinese conveyor belt manufacturer with 16 years of industry experience, Annilte is proud to hold both ISO quality management certification and ISO 14001 environmental management certification. Our manufacturing facilities meet “Green Factory” standards, and we are also an internationally recognized SGS Gold Supplier.

We offer a comprehensive range of customizable belt solutions under our own brand "ANNILTE", designed to meet diverse industrial needs.

Should you require further information about our products or capabilities, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Jan-09-2026