In the precision-driven world of metal finishing, the efficiency of your vacuum metal polishing machine hinges on a critical yet often overlooked component: the conveyor belt. A high-quality, durable belt is not just an accessory; it's the backbone of a smooth, consistent, and cost-effective polishing process. Any compromise here can lead to downtime, defective products, and increased maintenance costs. This guide explores how Annilte's specialized conveyor belts are engineered to meet the extreme demands of vacuum metal polishing.

Why Vacuum Metal Polishing Puts Extreme Demands on Conveyor Belts

The environment inside a vacuum metal polishing machine is uniquely challenging. An ordinary belt simply won't hold up. The right belt must withstand:

4 Heavy Loads & Constant Friction: Metal components are heavy and abrasive, requiring belts with superior tensile strength and exceptional wear resistance.

4 High-Temperature Exposure: The polishing process generates significant heat, which can cause standard belts to degrade, harden, and fail prematurely.

4 Precision and Stability: Any belt slippage, tracking issues, or vibration translates directly into uneven polishing and inconsistent product quality.

4 Vacuum Environment Suitability: The belt material must be stable in a vacuum, resisting outgassing and maintaining its properties without contaminating the workspace.

Choosing the wrong belt means frequent replacements, unexpected, and ultimately, a negative impact on your bottom line.

Annilte Vacuum Metal Polishing Belts: Engineered for Peak Performance

At Annilte, we design our belts to be the most reliable part of your polishing line. Our vacuum metal polishing machine belts are built to excel where others fail.

Key Features of Annilte Belts:

Superior Abrasion & Tear Resistance

Constructed from high-strength synthetic materials and specialized weaving techniques, Annilte belts withstand continuous friction and impact, offering a service life that exceeds industry standards and reduces your long-term operating costs.

Excellent Dimensional Stability

We rigorously control thermal shrinkage and stretching. This ensures the belt maintains its exact dimensions during extended operation, eliminating tracking problems and guaranteeing precise, consistent polishing results.

High-Temperature Resistance

Our specialized compound formulations allow our belts to remain flexible and strong under polishing heat, preventing the premature cracking and embrittlement that plagues inferior products.

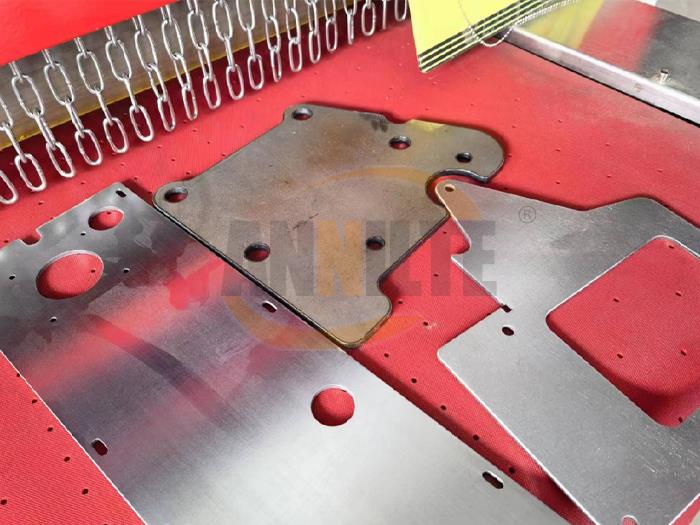

Precision Joint Technology

Whether seamless or with high-strength spiral joints, our belts run smoothly and without vibration. The joint is flawlessly smooth, ensuring it never marks or scratches your valuable metal surfaces.

Customizable Solutions

We understand that every machine and application is unique. Annilte offers a range of materials (e.g., high-performance polyester, nylon), thicknesses, and widths. We can provide custom-sized belts to ensure a perfect match for your specific equipment.

The Annilte Advantage: What You Gain

4 Increased Productivity: Minimize unplanned downtime and enable continuous, high-volume production runs.

4 Superior Finish Quality: A stable, consistent conveying surface is the foundation for achieving a uniform, defect-free polish on every piece.

4 Lower Total Cost of Ownership: Exceptional longevity and reduced failure rates mean fewer replacements and lower maintenance spending.

4 Expert Technical Support: The Annilte team provides end-to-end professional advice, from selection and installation to maintenance best practices.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Nov-25-2025