In the world of bridge construction, every detail matters—especially when it comes to material handling. Conveyor belts play a crucial role in transporting concrete, aggregates, and sealing materials like grout. However, without proper sealing and durability, belts can wear quickly, causing downtime and increased costs. That’s where Annilte steps in. As a leading conveyor belt manufacturer, we specialize in high-performance belts designed to handle grout seal applications efficiently, ensuring your bridge projects stay on schedule and within budget.

Why Grout Seal Matters in Bridge Construction

Grout seal is essential for filling gaps, stabilizing structures, and preventing water infiltration in bridges. During construction, conveyor belts are used to move grout mixtures from mixing stations to application sites. Belts that aren’t designed for this task can suffer from:

- Abrasion from abrasive grout materials

- Chemical degradation from sealants

- Moisture damage leading to belt slippage or failure

Annilte’s conveyor belts are engineered to resist these challenges, offering superior durability and reliability.

Annilte’s Innovative Solutions for Grout Seal Handling

Our belts feature advanced materials and designs tailored for construction environments:

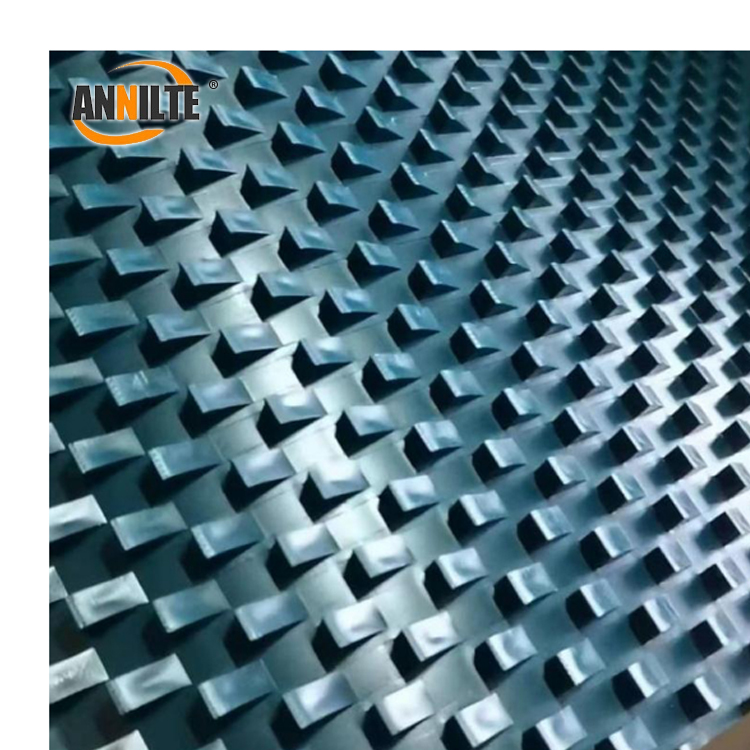

- Abrasion-Resistant Covers: Built to withstand the rough texture of grout and aggregates.

- Chemical-Resistant Layers: Protect against corrosive sealants and adhesives.

- Waterproof Design: Prevents moisture absorption, maintaining belt integrity in wet conditions.

- High-Tensile Strength: Supports heavy loads without stretching or tearing.

By using Annilte belts, construction teams can achieve smoother operations, reduced maintenance, and longer belt life—key factors in completing bridge projects successfully.

Real-World Benefits for Bridge Contractors

- Increased Productivity: Minimize downtime with belts that endure harsh conditions.

- Cost Savings: Reduce replacement frequency and maintenance expenses.

- Enhanced Safety: Reliable belts decrease the risk of onsite accidents.

- Sustainability: Durable materials mean less waste and a smaller environmental footprint.

Annilte is committed to supporting the construction industry with products that meet the highest standards. Whether you’re working on a small overpass or a major suspension bridge, our conveyor belts ensure that grout seal applications are handled seamlessly.

Choose Annilte for Your Next Project

Join countless construction firms that trust Annilte for their conveyor belt needs. Our expertise in grout seal applications makes us the ideal partner for bridge-building ventures. Contact us today to learn how our solutions can optimize your operations.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

As a leading Chinese conveyor belt manufacturer with 16 years of industry experience, Annilte is proud to hold both ISO quality management certification and ISO 14001 environmental management certification. Our manufacturing facilities meet “Green Factory” standards, and we are also an internationally recognized SGS Gold Supplier.

We offer a comprehensive range of customizable belt solutions under our own brand “ANNILTE,” designed to meet diverse industrial needs.

Should you require further information about our products or capabilities, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Jan-06-2026