What is a vacuum-assisted cutting table?

Vacuum-assisted cutting tables generate negative pressure via an underside vacuum pump, firmly securing materials to the surface. This ensures materials remain perfectly flat and immobile throughout the cutting process. This technology eliminates issues like obstruction and cumbersome operation associated with traditional clamps, making it ideal for precision processing of thin sheets, flexible materials, and non-metallic substances.

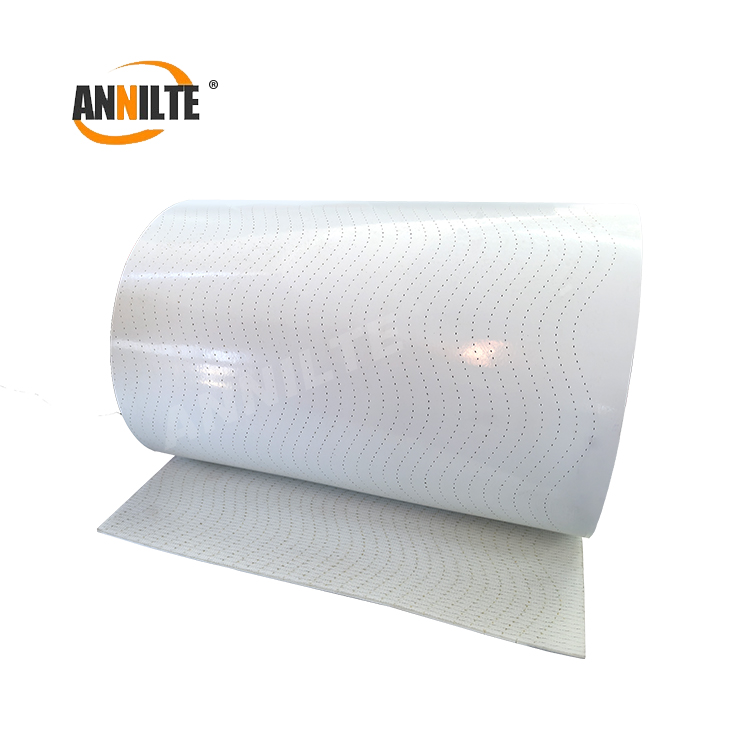

The key to efficient vacuum adhesion lies in the conveyor belt covering the table surface.

Why Choose Perforated PU Conveyor Belts?

Standard conveyor belts or unoptimized materials fail to meet vacuum suction requirements. Our perforated PU conveyor belts are the perfect solution engineered specifically for this application, offering these irreplaceable advantages:

Superior Sealing & Suction

Precision Perforation: Holes precisely punched according to your vacuum table's vent layout ensure vacuum pressure acts seamlessly on the material surface without leakage, delivering maximum and uniform suction force.

Secure Holding: Even lightweight, smooth materials like acrylic, film, or composites are firmly held in place, eliminating any micro-movement to guarantee smooth, burr-free cutting edges.

Exceptional Durability and Damage Resistance

Exceptional Puncture and Tear Resistance: PU (polyurethane) material is renowned for its outstanding abrasion resistance and physical damage tolerance, effectively withstanding minor scratches, molten debris, and laser scatter during cutting. Its lifespan significantly exceeds that of PVC or rubber materials.

Prevents Laser Penetration Damage: For laser cutting applications, the appropriate PU material effectively resists laser ablation, protecting the vacuum system beneath the table and extending the overall equipment lifespan.

Smooth Conveying Performance

Precise Positioning: The flat conveyor belt surface ensures accurate material alignment during entry and exit from the work zone, enabling seamless integration into automated production flows.

Low Elongation: High-quality PU belts exhibit minimal elongation, preventing hole misalignment and adhesion loss caused by stretching during prolonged use.

Easy Cleaning and Maintenance

The smooth surface resists debris and dust adhesion, allowing for quick sweeping or air gun cleaning. This minimizes downtime and maintains a tidy work environment.

Our Perforated PU Conveyor Belts Are Your Ideal Choice

We specialize in providing customized perforated PU conveyor belts for various industrial cutting equipment. Recognizing the unique demands of different machines, materials, and processes, we offer:

Customization Services: Precise tailoring based on your vacuum table dimensions, perforation patterns, and hole sizes.

Diverse Specifications: PU belts in varying thicknesses, hardness levels, and colors to suit laser cutting, waterjet cutting, blade cutting, and other applications.

Superior Quality & Support: Utilizing premium raw materials, we ensure every meter meets stringent industrial standards, backed by expert technical consultation and after-sales service.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Nov-20-2025