1. Superior Cut & Gouge Resistance: Defying Sharp Edges

Standard rubber belts are easily sliced, gouged, and torn by sharp materials like ores, metal scraps, and glass, leading to premature failure.

Our Solution: Our PU cut-resistant belts feature an exceptionally thick layer of polyurethane (PU)

with a high surface hardness. This physical property creates a tough, protective top cover that effectively resists penetration and tearing from sharp and abrasive materials. It is the ideal choice for transporting sintered ores, crushed stones, and scrap metal.

User Search Intent: "conveyor belt keeps splitting," "belt for sharp materials," "abrasion resistant conveyor belt"

2. Excellent Impact Resistance: A Robust Core for Heavy Loads

A hard surface alone isn't enough. The impact from heavy, lumpy materials dropped from height can damage the belt's core, causing hidden and catastrophic breaker fabric breaks.

Our Solution: We reinforce our PU belts with 2 to 3 layers of high-tensile strength fabric. This creates a sturdy and flexible carcass that absorbs and distributes impact energy, preventing ply separation, ripping, and rupture. This ensures maximum stability and safety under heavy-load conditions.

User Search Intent: "impact resistant conveyor belt," "heavy-duty conveyor belt," "belt for bulk material handling"

3. Inherent Oil & Grease Resistance: Thriving in Oily Environments

In industries like automotive manufacturing or machining, conveyor belts are exposed to oils, greases, and cutting fluids. Standard rubber degrades, swells, and loses strength upon contact with oil.

Our Solution: Thanks to the stable chemical structure of polyurethane, our belts offer inherent resistance to oils and greases. They maintain their physical integrity and dimensional stability, preventing the softening and degradation that plagues rubber belts in oily conditions.

User Search Intent: "oil resistant conveyor belt," "conveyor belt for greasy conditions," "PU belt oil resistance"

4. Outstanding Abrasion Resistance: Maximizing Service Life

Abrasion is the most common cause of conveyor belt wear. High abrasion rates lead to frequent replacements, increasing costs and unplanned downtime.

Our Solution: Polyurethane has one of the highest abrasion resistance ratings among polymer materials. Combined with the belt's inherent flexibility, this "tough yet supple" characteristic allows it to withstand surface wear from friction without developing stiff, brittle cracks. Its service life often outperforms standard rubber belts many times over, significantly reducing your Total Cost of Ownership.

User Search Intent: "high abrasion resistant belt," "long life conveyor belt," "reduce conveyor belt wear"

Why Choose Our PU Cut-Resistant Conveyor Belt?

We integrate these four core properties into one complete, reliable package. Whether you face a single challenge or a combination of cuts, impacts, oil, and abrasion, our PU Cut-Resistant Conveyor Belt is equipped to handle it, ensuring your production line runs continuously and efficiently.

Contact us today for a free technical consultation and sample testing! Let our experts diagnose your current conveying challenges and recommend the most cost-effective solution.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

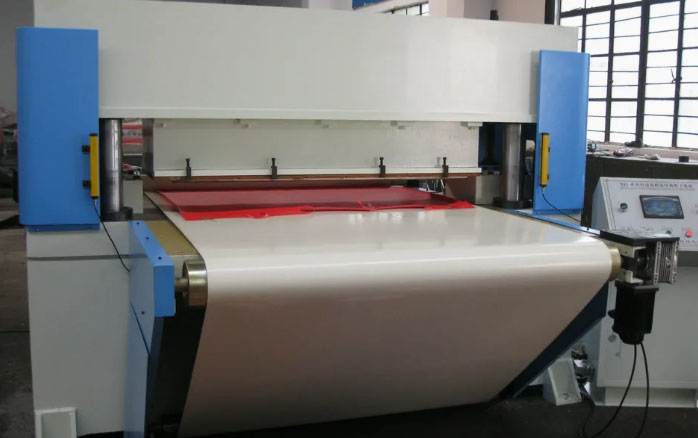

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Nov-17-2025