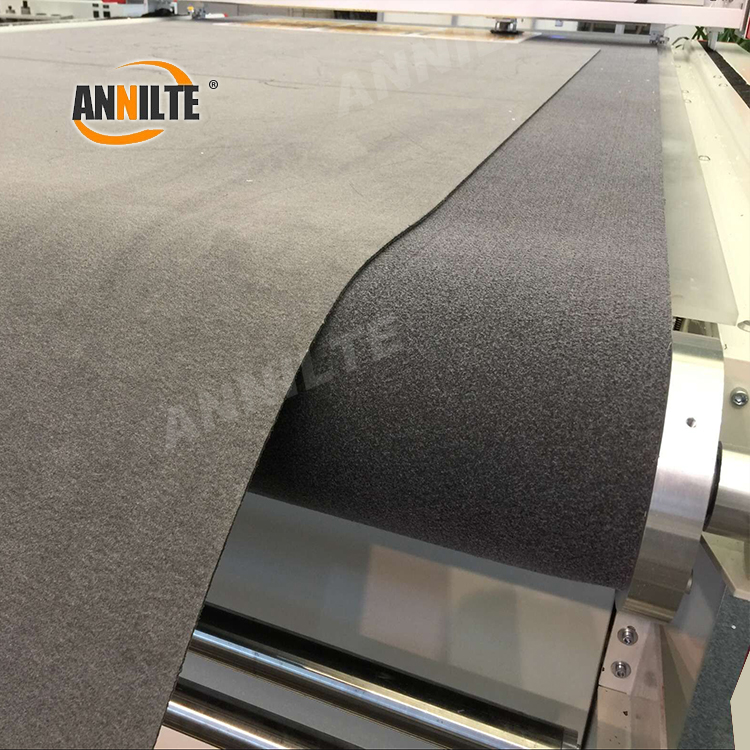

The Perfect Partner for Automated Cutting Machines: Custom-Made Automatic Feeding Table Felt Pads for Lectra/Zund/Esko

In today's high-speed digital cutting workshops, efficiency is life and precision is dignity. Your high-end Lectra, Zund, or Esko automated cutting machine is the heart of productivity—but have you ever paid attention to that unsung yet crucial component: the automatic feeding table felt pad?

Unlike standard cutting pads, the Automatic Feeding Table Felt Pad is engineered specifically for continuous, high-speed automated production environments. It addresses these core pain points:

Ultimate Protection, Eliminating Scratches

During automatic feeding, materials (especially premium leather, glossy films, carbon fiber, etc.) frequently rub against the table surface.

Solution: Our high-density fiber felt pad features a velvety-soft surface that forms a cushioning layer. This effectively prevents scratches or indentations during material transport, ensuring flawless cutting results for every piece.

Precise Feeding, Slip Prevention

Smooth materials like silk or coated fabrics can slip on conveyor belts, causing cutting misalignment and significant waste.

Solution: The felt pad surface provides optimal friction. It allows materials to be pushed smoothly and effortlessly while offering sufficient grip to ensure precise positioning under the cutting head, eliminating accuracy loss caused by slippage.

Extend Tool Life, Reduce Operating Costs

Hard work surfaces accelerate wear on blades and oscillating knives.

Solution: The resilient material of the felt pad provides an ideal “soft landing” platform for cutting tools. It ensures the cutting edge fully penetrates the material while avoiding direct impact with the hard surface, significantly extending the lifespan of expensive tools and saving you substantial consumable costs.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Oct-11-2025