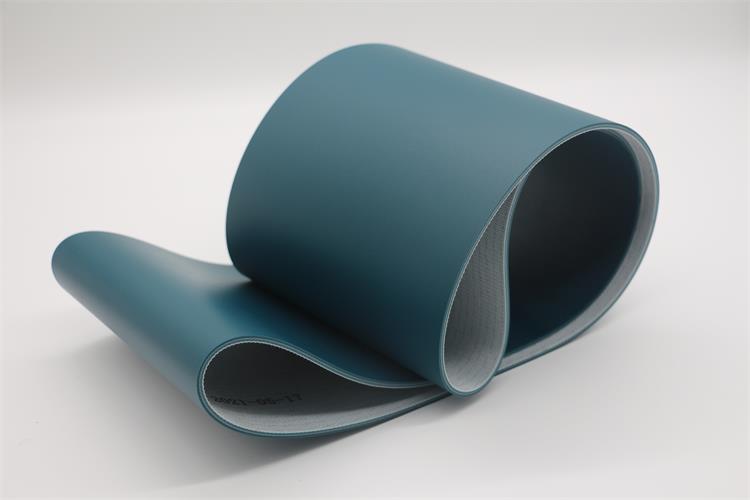

During autumn and winter, dry air conditions heighten the risk of static electricity on production lines. Particularly in cleanrooms, semiconductor manufacturing, and electronics assembly, static not only damages precision products but also compromises production safety and efficiency. A reliable anti-static conveyor belt has thus become an essential component in many manufacturing processes.

Once, a customer approached us with an urgent need. The material he required transporting was highly specialized—explosive boxes. This imposed extremely stringent demands on the conveyor belt's anti-static performance: the index must consistently reach 10⁶ (10 to the power of 6). However, after searching the market, he discovered that most commonly available “anti-static” conveyor belts only achieved performance levels around 10⁸ (10 to the power of 8), failing to meet his safety requirements.

Upon learning of the situation, our product manager immediately visited the customer's site for in-depth discussions about the specific operating conditions and concerns. Ultimately, we matched him with Anatech's custom anti-static conveyor belt. This product utilizes specialized materials and manufacturing processes to achieve a stable anti-static index of 10⁵-10⁶, backed by authoritative third-party testing reports that let the data speak for itself. After implementation, the client expressed satisfaction with the operational results. The trust established through this collaboration continues to this day, and we maintain an excellent working relationship.

This case study clearly demonstrates the core advantages of Annilte's anti-static conveyor belts:

1. High Anti-Static Index

Through specialized materials and processes, the anti-static index remains stable at 10⁵-10⁶, significantly outperforming standard anti-static belts. Verified test reports ensure data reliability.

2. Customization to Specific Requirements

We offer tailored solutions such as edge finishing based on client needs, effectively preventing fraying and shedding along the belt edges. This prevents contamination in clean production lines and enables adaptation to more complex application scenarios.

3. Extensive Application Range

From ultra-cleanrooms and semiconductor manufacturing demanding extreme cleanliness to nonwoven fabric and electronics assembly lines, Annilte anti-static conveyor belts effectively prevent product damage and production risks caused by static buildup, ensuring safer and more stable operations.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Oct-31-2025