In the demanding world of leather tanning and hide processing, consistency is everything. Every stage—from soaking and liming to tanning and fatliquoring—requires precise control to ensure the final product meets exacting quality standards. The wringing or setting-out process is particularly critical, where excess moisture, chemicals, or oils must be uniformly removed to prepare hides for the next phase.

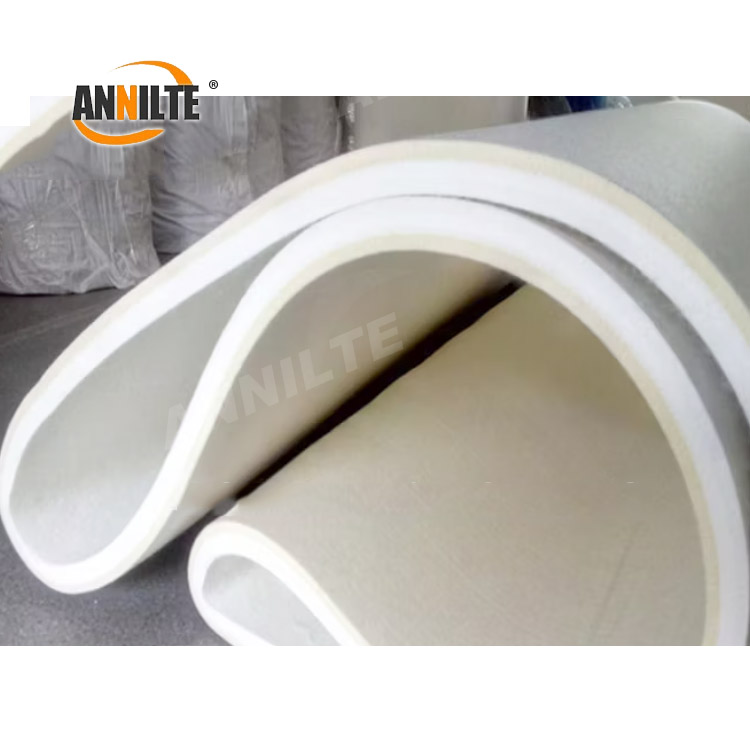

An inefficient or unreliable wringing machine belt can lead to uneven moisture content, processing defects, and costly production downtime. At Annilte, we engineer specialized conveyor belts that deliver the precision, durability, and performance your tannery demands.

Why Annilte Belts Are the Preferred Choice for Leather Wringing Machines

- Exceptional Grip & Uniform Pressure: Our belts are designed with surface textures and materials that provide consistent, slip-resistant contact with wet hides. This ensures even pressure across the entire surface for uniform water and solution removal, which is vital for consistent dye uptake and finishing.

- Superior Chemical & Abrasion Resistance: Tannery environments are harsh, with exposure to acids, alkalis, salts, and fats. Annilte belts are manufactured from compounds specifically formulated to resist chemical degradation and physical abrasion from hides, dramatically extending belt life and reducing replacement frequency.

- Optimized for Efficient Water Removal: The construction of our belts facilitates efficient fluid drainage and release. This enhances the wringing effectiveness, leading to shorter drying times, reduced energy consumption in downstream drying processes, and more efficient chemical usage.

- Minimal Stretch & High Dimensional Stability: We understand that belt slippage or stretch compromises the wringing gap accuracy. Annilte belts are built to maintain their tension and dimensions under constant load and variable moisture conditions, ensuring reliable operation and consistent output hour after hour.

- Easy to Clean & Maintain: Our belts are designed to shed residual particles and are easy to clean, helping maintain hygiene standards in your processing line and preventing cross-contamination between different batches or chemicals.

Applications in Leather & Hide Production:

- Setting-Out Machines: For removing excess water after washing or dyeing.

- Sammying & Wringing Machines: For mechanically dewatering hides after various wet processing stages.

- Fatliquoring & Oiling Uniformity: Ensuring even distribution and removal of excess oils.

Drive Efficiency and Quality in Your Tannery

Don’t let an underperforming belt become the weak link in your precision leather processing line. Upgrading to an Annilte wringing machine belt is an investment in product quality, production efficiency, and lower total operating costs.

Engineered for Your Specific Machine

We provide belts tailored to fit major OEM wringing and setting-out machines, with customization available for width, thickness, and surface characteristics.

Ready to Enhance Your Leather Processing?

Contact Annilte today. Our technical specialists can help you select the perfect belt for your machine and application. Request a free consultation or a custom quote to experience the Annilte difference.

Annilte – Precision in Motion for Industry.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

As a leading Chinese conveyor belt manufacturer with 17 years of industry experience, Annilte is proud to hold both ISO quality management certification and the RoHS environmental directive. Our manufacturing facilities meet “Green Factory” standards, and we are also an internationally recognized SGS Gold Supplier.

We offer a comprehensive range of customizable belt solutions under our own brand "ANNILTE", designed to meet diverse industrial needs.

Should you require further information about our products or capabilities, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Jan-27-2026