Annilte TPEE Conveyor Belts represent a fundamental advancement in material science, offering a solution that combines the durability of rubber with the precision of engineered thermoplastics. Designed to withstand extreme temperatures, resist chemical degradation, and maintain performance under continuous operation, these belts address the most persistent pain points across multiple sectors.

Understanding TPEE: The Superior Material Advantage

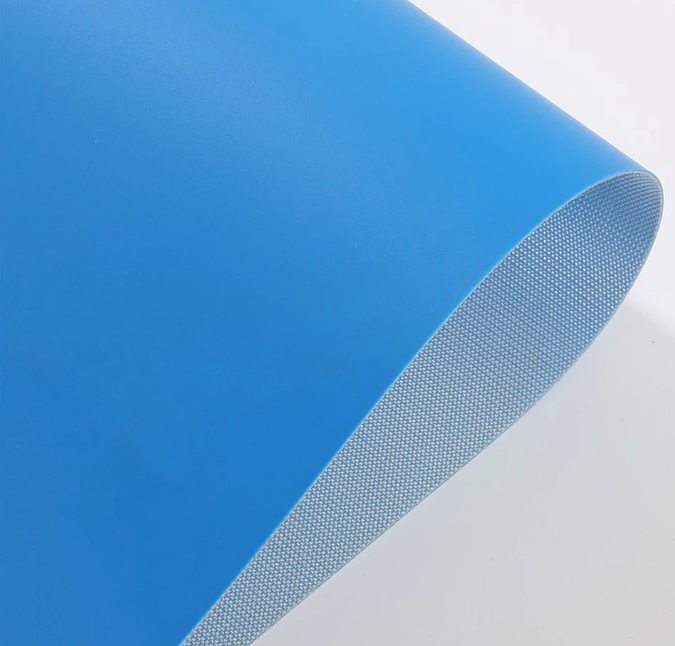

TPEE (Thermoplastic Polyester Elastomer) is a hybrid polymer that combines the elastic resilience of rubber with the processability and precision of engineering plastics. This unique molecular structure provides exceptional physical properties absent in conventional belt materials.

Annilte harnesses these inherent advantages to create conveyor belts that consistently outperform alternatives:

- Temperature resilience (-55°C to +160°C)

- Chemical and oil resistance

- Low elongation, high strength

Material Comparison

| Property | TPEE (Annilte) | PVC | Rubber |

|---|---|---|---|

| Temperature Range | -55°C to +160°C | 0°C to 70°C | -25°C to 80°C |

| Chemical/Oil Resistance | Excellent | Poor to Fair | Fair to Good |

| Tensile Strength | High | Medium | Medium-High |

| Hygiene & Cleanability | Non-porous, Easy to Clean | Porous, Hard to Disinfect | Porous, Absorbs Liquids |

| Customization Flexibility | Very High | Medium | Low |

Annilte Customization: Engineering Solutions for Your Unique Needs

Beyond standard offerings, Annilte provides comprehensive customization capabilities:

- Dimensional Specifications: Precise width, length, and thickness configurations

- Surface Textures: Cleated, rough top, or specialized patterns for incline applications

- Accessory Integration: Cleats, sidewalls, and guide profiles incorporated during manufacturing

- Material Modifications: Specialized compounds for specific chemical, thermal, or static requirements

This custom engineering approach ensures seamless integration with equipment from leading manufacturers like Siemens, Bosch, Omron, and Rockwell Automation.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

As a leading Chinese conveyor belt manufacturer with 17 years of industry experience, Annilte is proud to hold both ISO quality management certification and the RoHS environmental directive. Our manufacturing facilities meet “Green Factory” standards, and we are also an internationally recognized SGS Gold Supplier.

We offer a comprehensive range of customizable belt solutions under our own brand "ANNILTE", designed to meet diverse industrial needs.

Should you require further information about our products or capabilities, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Jan-29-2026