With the growing global demand for renewable energy, PV power generation has become an important part of China's new energy system. However, PV panels are exposed to the outdoors for a long time and are prone to accumulate dust, oil, bird droppings and other pollutants, which seriously affects power generation efficiency. The traditional manual cleaning is not only inefficient and costly, but also has the safety hazard of working at height. For this reason, more and more PV power stations are adopting PV cleaning robots for automated cleaning.

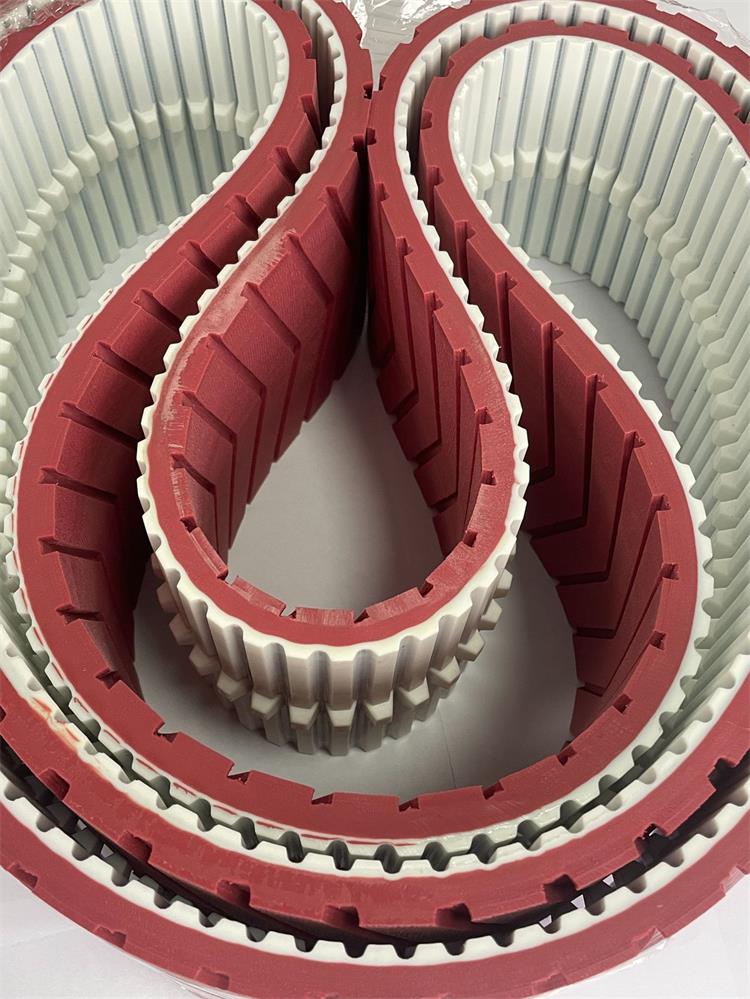

Annilte has developed a PV cleaning robot crawler, which can operate stably even on a 17° slope to ensure efficient cleaning.

Role of PV cleaning robot tracks

The tracks are specially designed for PV cleaning robots and have the following features:

Strong anti-slip: the special pattern design enhances the friction, preventing the robot from slipping and ensuring safe operation.

Good fit: Increase the contact area with the PV panels to improve the cleaning effect.

Stable and durable: adapting to different terrains, ensuring long-term reliable operation.

Core advantages of PV cleaning robot tracks

1、Excellent anti-skid performance

Special anti-skid pattern design, strong grip, can easily cope with 17° slopes without slipping or shifting.

2、Excellent wear resistance

Adoption of high-strength materials, not easy to wear and tear in long-term use, avoiding problems such as skinning and block dropping.

3、Strong weather resistance

Resistant to ultraviolet rays, high and low temperatures, whether it is cold or hot, the performance is always stable.

4、Firm structure

The rubber sheet and synchronous belt are tightly combined, not easy to delamination, to ensure long-term use without deformation.

Application Scenarios of PV Cleaning Robot Tracks

Annilte PV cleaning robot tracks can be applied to a variety of PV plant scenarios, including:

Agricultural photovoltaic

Rooftop and greenhouse photovoltaic

Mountain photovoltaic

Fishpond photovoltaic

Factory photovoltaic

High-pile photovoltaic

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Jun-16-2025