In today’s fast-growing recycling industry, efficiency and accuracy in sorting are critical. Whether you're processing post-consumer PET bottles or managing an advanced material recovery facility (MRF), the conveyor belt you choose can make or break your operation. Annilte specializes in manufacturing high-performance PET Bottle Sorting Conveyor Belts designed to meet the rigorous demands of recycling plants and integrate seamlessly with leading brand sorting machines.

Why Sorting Efficiency Matters – The Industry Pain Points

Many recycling facilities struggle with:

- Bottle slippage and misalignment on the conveyor, causing sorting errors and reduced purity of output.

- Excessive wear and tear due to sharp edges, moisture, and continuous operation.

- Frequent maintenance downtime, disrupting throughput and increasing operational costs.

- Noise and vibration issues that affect worker comfort and machine longevity.

- Incompatibility with optical sorters, AI-based robots, or ballistic separators from brands like TOMRA, Pellenc ST, Steinert, or Bühler.

These pain points lead to lower material purity, higher operational costs, and missed recycling targets.

How Annilte’s PET Bottle Sorting Conveyor Belt Solves These Problems

Annilte engineering focuses on precision, durability, and smooth integration. Our belts are crafted to ensure bottles remain stable, correctly oriented, and perfectly presented to sensors and sorters.

Key Features:

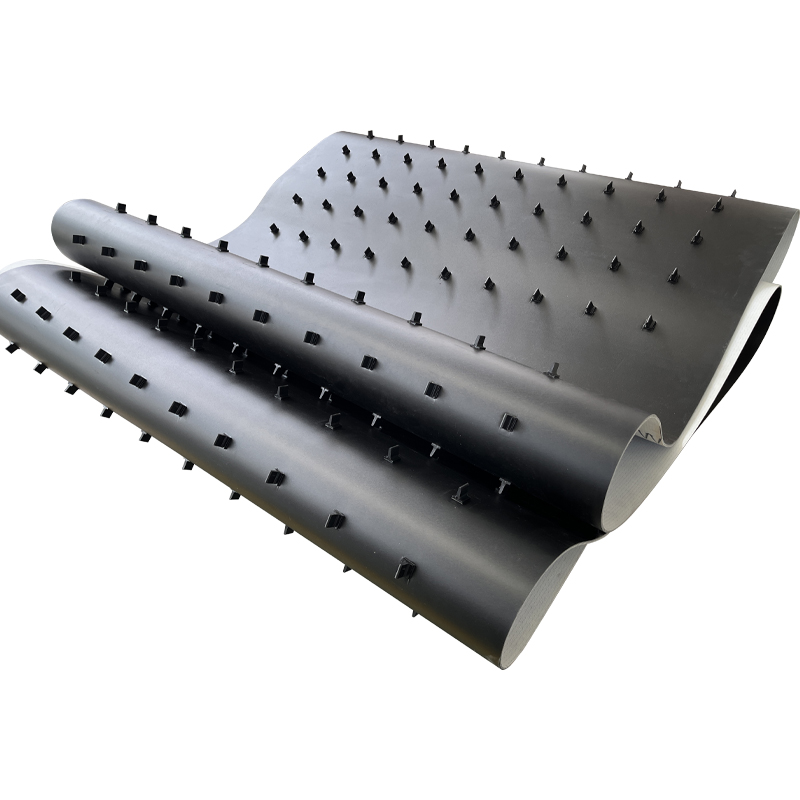

- Anti-slip Surface Design: Proprietary top cover materials ensure bottles stay in place without rolling or tipping, even at high speeds.

- Abrasion & Moisture Resistance: Specially formulated rubber or polymer compounds resist cuts, scratches, and degradation from wet or contaminated bottles.

- Low Stretch & High Tensile Strength: Reinforced with polyester (PET) or polyamide fabric to maintain dimensional stability under heavy loads.

- Quiet Operation: Optimized for minimal noise, improving the working environment.

- Easy Installation & Maintenance: Designed for quick replacement and reduced downtime.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

As a leading Chinese conveyor belt manufacturer with 17 years of industry experience, Annilte is proud to hold both ISO quality management certification and the RoHS environmental directive. Our manufacturing facilities meet “Green Factory” standards, and we are also an internationally recognized SGS Gold Supplier.

We offer a comprehensive range of customizable belt solutions under our own brand "ANNILTE", designed to meet diverse industrial needs.

Should you require further information about our products or capabilities, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Feb-07-2026