In the high-stakes world of apparel, automotive interiors, and technical textiles, precision is everything. Your Gerber cutting system is a major investment, designed to deliver speed and accuracy. However, even the most advanced cutter can underperform if paired with the wrong conveyor belt.

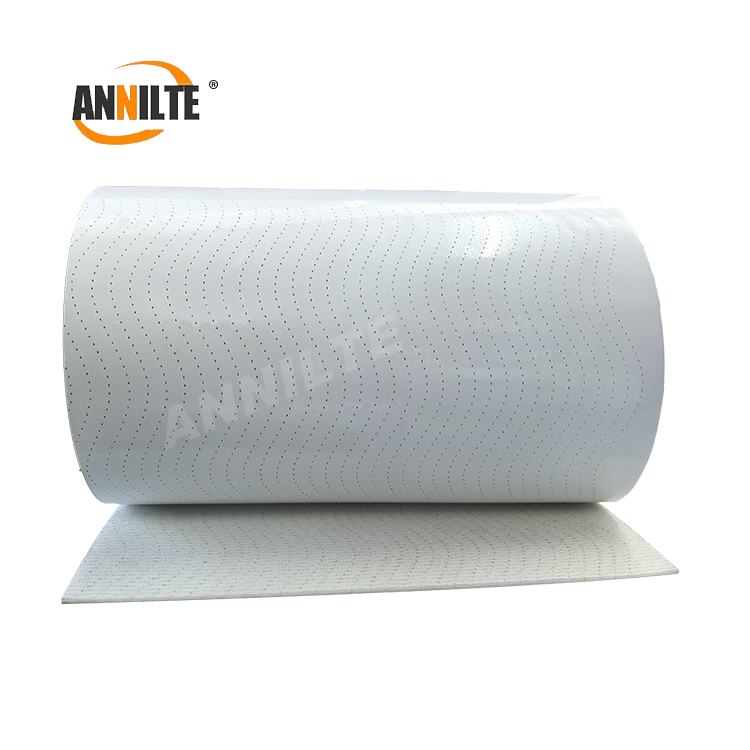

At Annilte, we specialize in engineering perforated conveyor belts that unlock the full potential of your Gerber cutting machine. Our belts are not just components; they are precision tools designed for one critical job: holding fabric perfectly stationary during the cutting process.

Why Annilte Perforated Belts are the Industry's First Choice:

- Unmatched Grip & Stability: Our precisely engineered perforation patterns create optimal vacuum hold-down. This eliminates fabric shifting, puckering, or creeping, ensuring every cut—from delicate silks to heavy canvases—is razor-sharp and perfectly aligned. Say goodbye to material waste and costly re-cuts.

- Enhanced Durability for Demanding Environments: Made from high-grade materials, Annilte belts resist stretching, wear, and oil/chemical exposure. They maintain their dimensional stability and perforation integrity far longer than standard belts, translating to lower long-term costs and reduced downtime for belt replacements.

- Superior Airflow Design: Consistent vacuum is key. Our perforation geometry is optimized to provide uniform suction across the entire cutting bed, crucial for multi-ply cutting. This guarantees that even the bottom layer of a fabric stack is held firmly, ensuring clean cuts throughout.

- Easy Maintenance & Long Service Life: We design for real-world workshops. Our belts are easy to clean and maintain, resisting debris buildup in the perforations. Their robust construction means they withstand the daily rigors of high-volume production, offering a superior return on investment.

Is It Time to Replace Your Gerber Cutting Belt? Look for These Signs:

- Visible wear, tears, or stretched perforations.

- Frequent fabric slippage during cutting.

- Inconsistent cut quality, especially on multi-layers.

- Reduced vacuum efficiency, leading to higher energy use.

- Excessive downtime for belt cleaning or adjustment.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 16 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Dec-30-2025