Egg Collection Belt Manufacturer | Custom Egg Conveyor | Annilte Brand

For poultry farm managers, inefficient egg collection isn't just an operational hassle—it directly impacts profitability through labor costs and breakage losses. At Annilte, we engineer high-performance Egg Collection Belts designed to maximize your farm's output and protect your bottom line by ensuring gentle, reliable transport from cage to packing station.

The Core Challenge: Manual Collection vs. Automated Efficiency

Manual egg collection in large-scale layer operations is time-consuming and increases the risk of damage. Even careful handling can lead to hairline cracks or breakages, turning potential revenue into loss. Modern farms are turning to automated systems to solve these issues, and the conveyor belt is the critical component that determines the system's success.

How Annilte's Engineered Belts Solve Farm Pain Points

Our belts are not just strips of material; they are precision components. We focus on three outcomes that matter most to you:

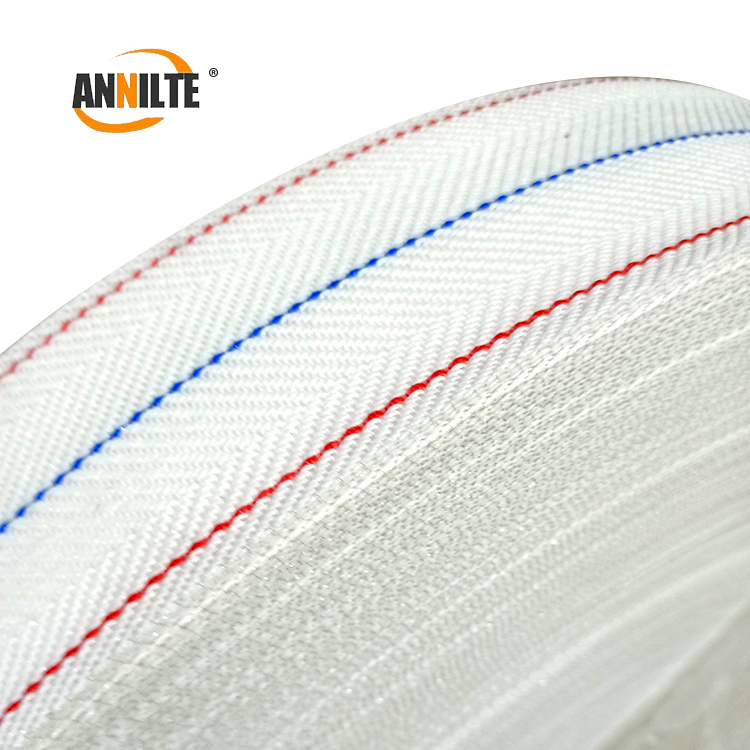

- Drastically Reduce Egg Breakage: The smooth, consistent surface of our polypropylene and polyester belts provides a stable bed for eggs. Unlike rigid conveyors, our belts offer slight cushioning and prevent rolling and collisions, significantly lowering breakage rates compared to manual handling or inferior systems.

- Slash Labor Costs & Increase Throughput: Automate the most repetitive task on your farm. Our belts integrate seamlessly with your existing cage rows and motor systems, continuously and gently moving eggs to a central collection point. This frees up your workforce for higher-value tasks and allows for the management of larger flocks.

- Ensure Hygiene & Durability: Made from high-quality, easy-to-clean materials, our belts support farm hygiene protocols. Their robust construction resists wear from constant use and exposure to the farm environment, ensuring a long service life and reliability.

Key Features of Annilte Egg Collection Belts

- Gentle & Stable Transport: Designed to prevent eggs from rolling or jostling, ensuring they arrive intact.

- Customizable for Perfect Fit: We understand that every farm layout is unique. Our belts are available in custom widths (from 90mm to 200mm) and lengths to fit any cage system configuration.

- Durable & Low-Maintenance Materials: Constructed from strong, food-safe polypropylene or polyester for longevity and easy cleaning.

- Easy Integration: Engineered for straightforward installation into new or existing poultry house automation setups.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 16 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Dec-12-2025