Is chemical spillage, corrosive slurry, or harsh cleaning agents ruining your conveyor belts? Premature wear, cracking, and delamination in acidic or alkaline environments lead to frequent downtime, safety risks, and soaring replacement costs.

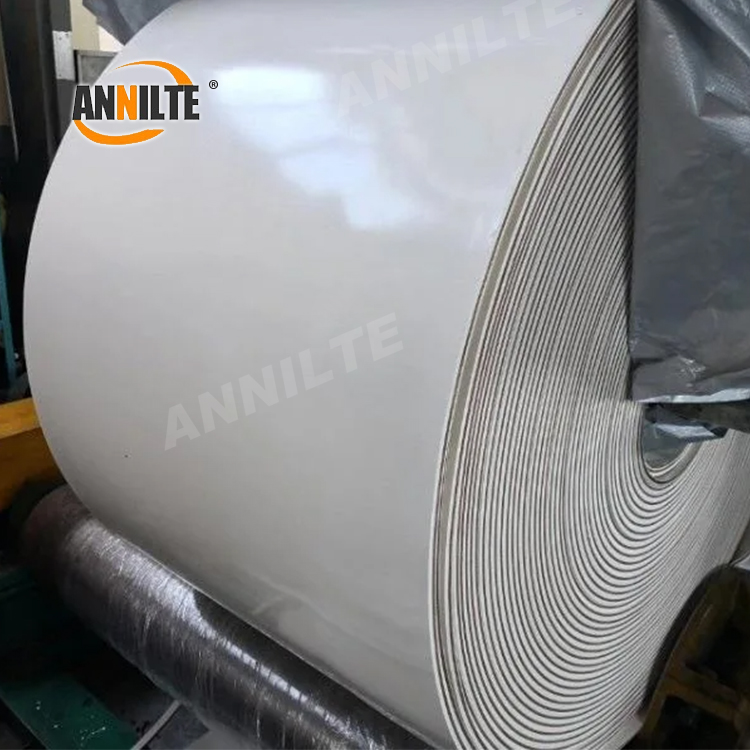

At Annilte, we understand these challenges deeply. That’s why we engineered our Acid and Alkali Resistant Conveyor Belts to be the robust, reliable, and cost-effective solution for industries operating in demanding conditions.

Why Standard Belts Fail in Chemical Environments

Ordinary rubber conveyor belts deteriorate rapidly when exposed to acids (like sulfuric or hydrochloric) or alkalis (like sodium hydroxide). This causes loss of tensile strength, cover cracking, and eventual belt failure, disrupting your entire production line.

Annilte’s Solution: Engineered for Resilience

Our specialized resistant belts are not just coated; they are compounded from the core up using select polymers and high-quality rubber (such as EPDM or specially formulated NR/SBR) that offer exceptional resistance to a wide range of chemicals.

Here are the 5 features that set Annilte belts apart:

- Superior Cover Compound: The specially formulated cover provides an impermeable barrier against corrosive chemicals, minimizing absorption and protecting the inner carcass.

- Excellent Tensile Strength Retention: Even after prolonged exposure, our belts maintain their structural integrity and load-bearing capacity, ensuring consistent performance.

- Resistance to Swelling & Cracking: The compound resists the swelling and hardening that lead to edge cracking and cover stripping, dramatically extending belt life.

- Durable Carcass Options: We use strong polyester (EP) or nylon (NN) fabric plies, treated for chemical resistance, ensuring excellent dimensional stability and impact resistance.

- Proven Performance in Key Industries: Our belts are trusted in Chemical Processing, Fertilizer Production, Mining & Ore Processing, Wastewater Treatment Plants, and Battery Manufacturing.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 16 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Dec-10-2025