What is an Automatic Feeding Adhesive Felt Pad?

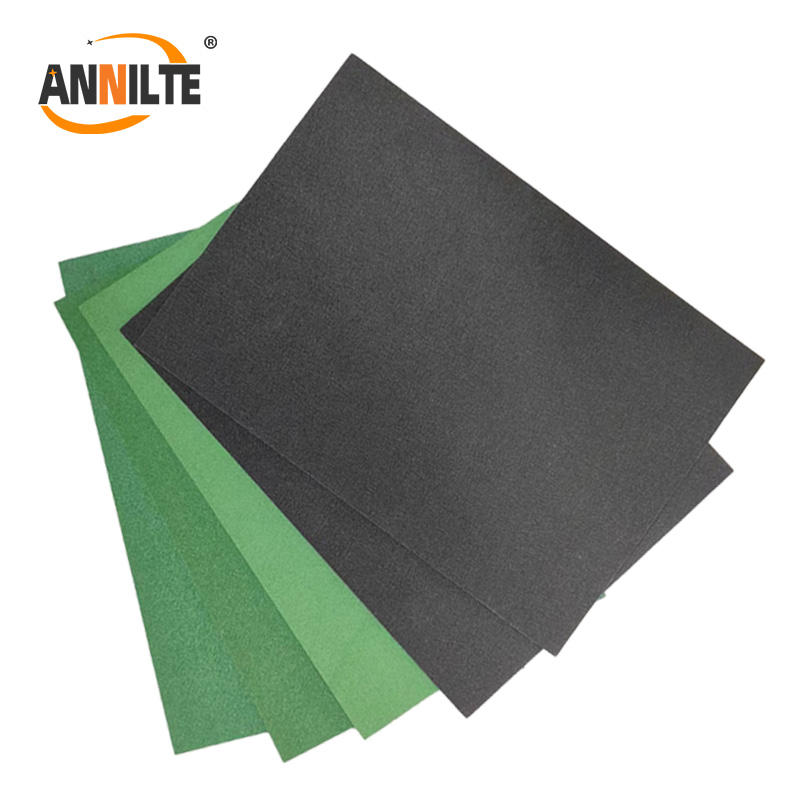

An automatic feeding adhesive felt pad is a vacuum-adhesive work surface material specifically designed for CNC routers, engraving machines, and various machining centers. Typically made from high-quality synthetic fiber felt, its surface is covered with microscopic pores. When connected to a vacuum pump system, it generates a powerful, uniform adhesive force that securely holds workpieces to the workbench.

The “automatic feeding” feature enables integration with automated equipment for continuous, automatic feeding of roll or sheet materials. This significantly reduces manual intervention and downtime, making it particularly suitable for large-scale batch production.

Why choose 4mm and 2.5mm thicknesses?

Thickness is a key parameter when selecting an adhesive felt pad, with 4mm and 2.5mm being the two most common and versatile specifications.

4mm Thickness: Offers greater rigidity and deeper tolerance for errors. This is especially crucial for penetrative machining (e.g., cutting, drilling), effectively preventing tool damage to the workbench surface after penetrating the workpiece and extending equipment lifespan. Its thicker structure also better compensates for minor workbench surface irregularities, ensuring uniform distribution of suction force.

2.5mm Thickness: Emphasizes flexibility and cost-effectiveness. Thinner and lighter, it responds more quickly during vacuum suction, providing optimal holding force for thinner or lighter workpieces (e.g., acrylic sheets, PCB boards, thin wood panels). Additionally, its material cost is typically lower, making it more cost-effective while maintaining performance.

Typical Applications

PCB Separation & Drilling: Securely holds circuit boards to prevent warping or shifting, ensuring precision in drilling and milling operations.

Aluminum Composite Panel & Acrylic Cutting: Protects the material's glossy finish while providing stable adhesion, resulting in smooth, burr-free edges.

Woodworking Engraving and Cutting: Securely holds MDF, solid wood, and plywood for intricate relief carving or precision cutting.

Non-metallic Composite Processing: Ideal for damage-free clamping and high-precision machining of materials like carbon fiber sheets and G10.

Lightweight Metal Fabrication: Offers reliable holding solutions for thin aluminum sheets, copper plates, and similar materials.

R&D Team

Annilte has a research and development team consisting of 35 technicians. With strong technical research and development capabilities, we have provided conveyor belt customization services for 1780 industry segments, and gained recognition and affirmation from 20,000+ customers. With mature R&D and customization experience, we can meet the customization needs of different scenarios in various industries.

Production Strength

Annilte has 16 fully automated production lines imported from Germany in its integrated workshop, and 2 additional emergency backup production lines. The company ensures that the safety stock of all kinds of raw materials is not less than 400,000 square meters, and once the customer submits an emergency order, we will ship the product within 24 hours to respond to the customer's needs efficiently.

Annilte is a conveyor belt manufacturer with 15 years of experience in China and an enterprise ISO quality certification. We are also an international SGS-certified gold product manufacturer.

We offer a wide range of customizable belt solutions under our own brand, "ANNILTE."

Should you require further information regarding our conveyor belts, please do not hesitate to contact us.

WhatsApp: +86 185 6019 6101 Tel/WeChat: +86 185 6010 2292

E-mail: 391886440@qq.com Website: https://www.annilte.net/

Post time: Oct-23-2025